Breadcrumbs

Jumper storage tower

Optimize space and time with the Jumper storage tower!

The fast and powerful JUMPER tower is the perfect solution for automating the storage of your heavy, heterogeneous-volume components so that you can:

- Optimize your storage space (up to 91% less space occupied)

- Reduce risk of civilian incidents

- Secure your products and reduce picking errors

- Simplify your stock management through our GSTOCK WMS software

- Increase your productivity

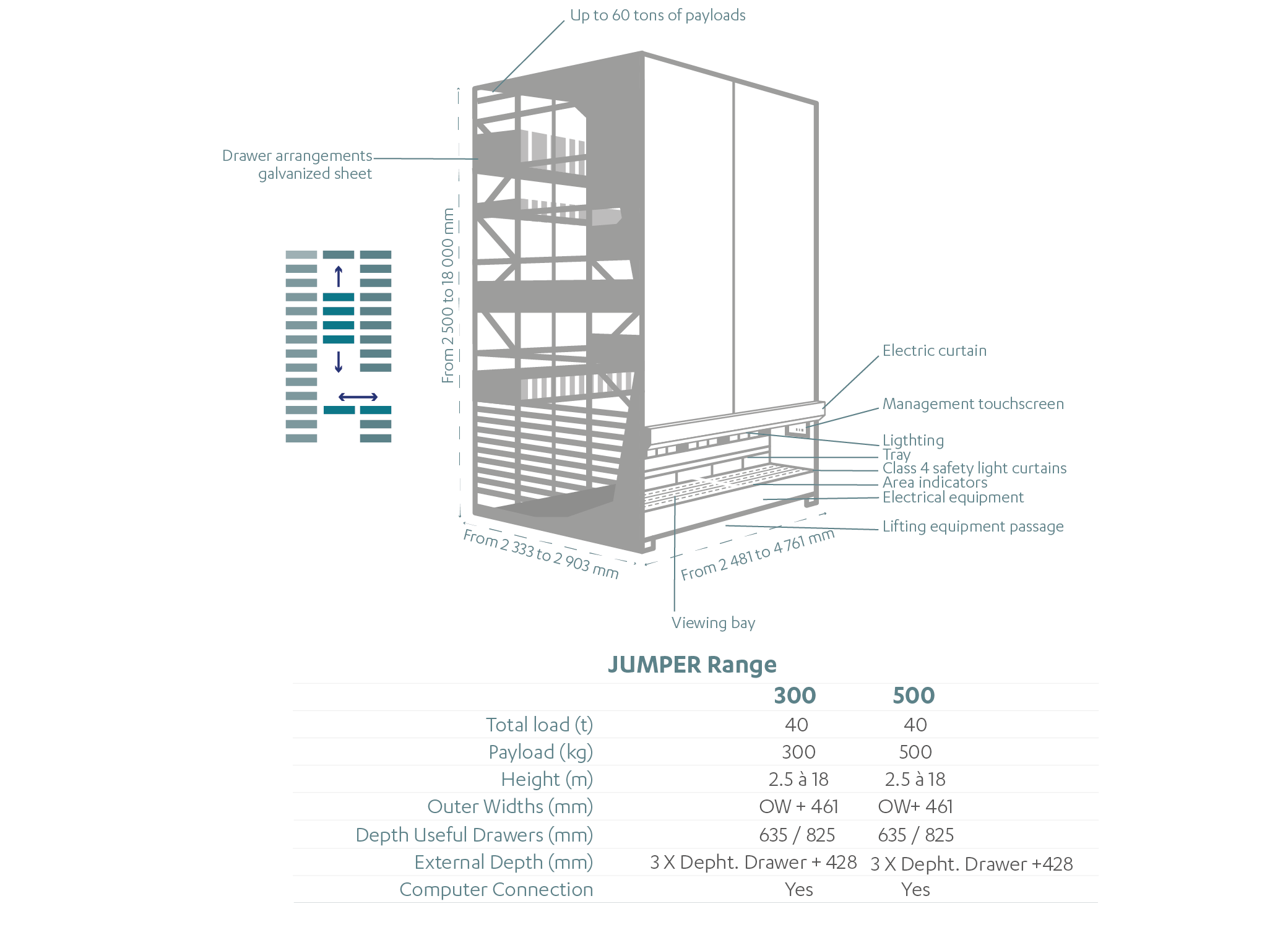

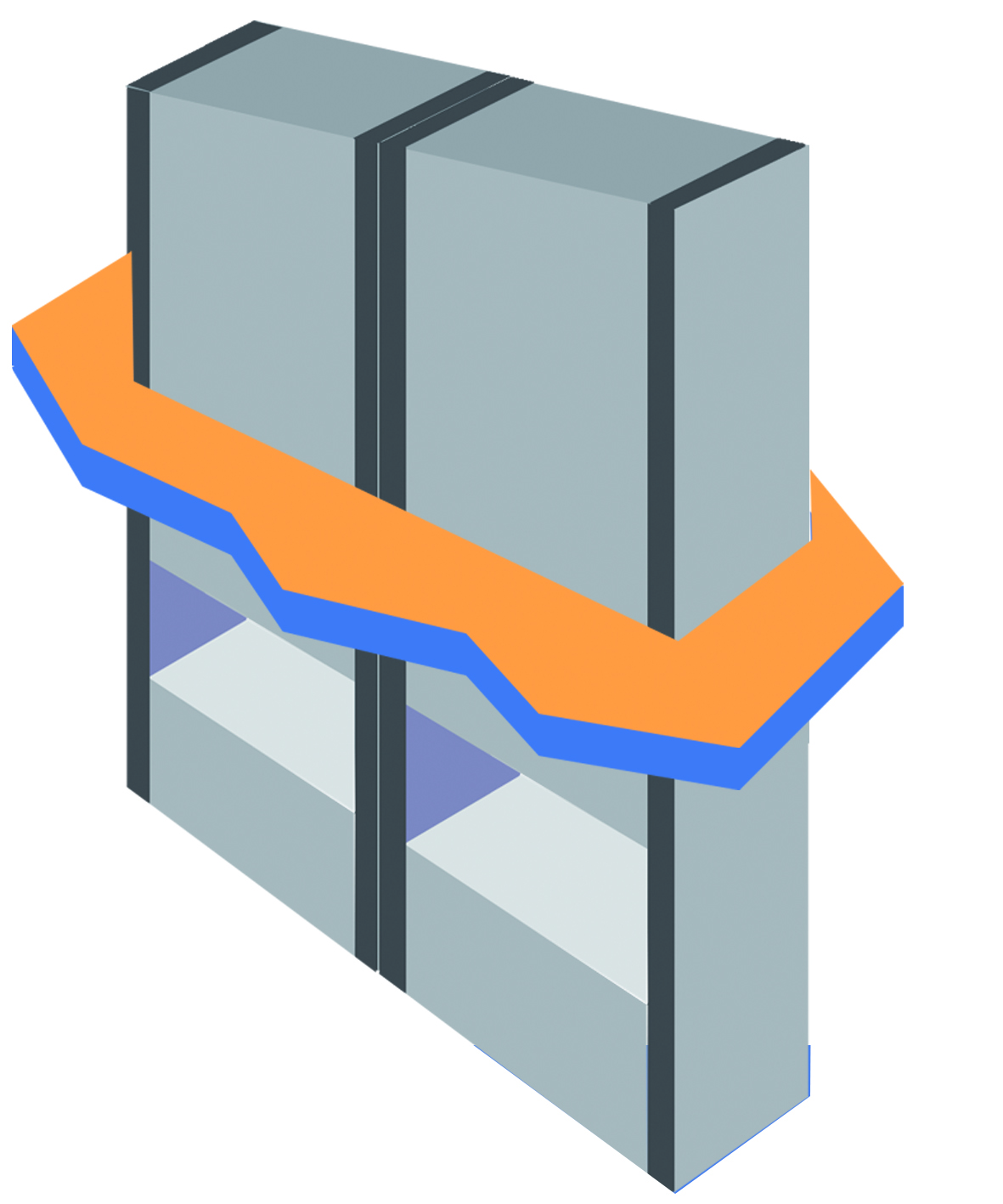

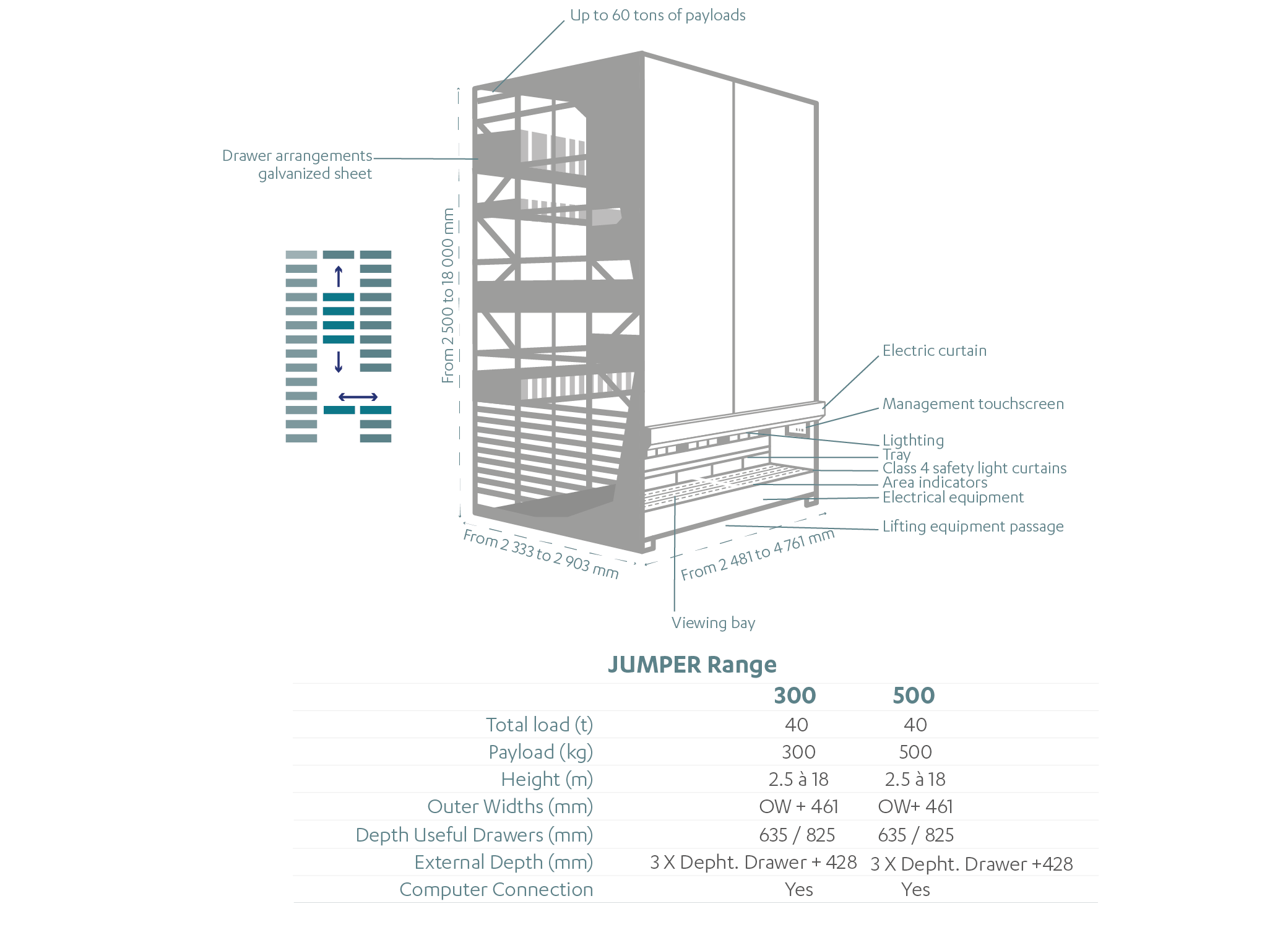

In storage structure which can take up to 60 tons, the mobile lifting platform moves vertically between the two storage volumes and removes the drawers to place them on the viewing station, designed to prevent musculoskeletal disorders and injuries.

The fast and powerful JUMPER tower is the perfect solution for automating the storage of your heavy, heterogeneous-volume components so that you can:

- Optimize your storage space (up to 91% less space occupied)

- Reduce risk of civilian incidents

- Secure your products and reduce picking errors

- Simplify your stock management through our GSTOCK WMS software

- Increase your productivity

In storage structure which can take up to 60 tons, the mobile lifting platform moves vertically between the two storage volumes and removes the drawers to place them on the viewing station, designed to prevent musculoskeletal disorders and injuries.

Customer issues

Would you like to automate your maintenance parts store?

The heterogeneity of maintenance parts as well as their occasionally sizeable load means proposing storage machines which are flexible, robust and secure. The JUMPER storage solution takes up to 500 kg effective load per shelf without the need for homogeneous load distribution on shelves (mechanically-welded structure). The rack and pinion assembly means there is no risk of accident (transmission belt breaking, etc.) and, at the same time, reduces the need for servicing. As such, you now have a storage solution which is perfectly tailored to even the most extreme environments.

Grasping hold of the mechanical devices may be made easier through the options for removing from drawers outside the tower: As such, you can collect your parts using a hoist, a jack or robotic arm.

Would you like to secure the spare part management for all your vehicles?

Large quantities of spare parts in your garage often means having a large storage area available and putting together your kits can take you a considerable length of time. The various widths and depths of the tower's shelves mean we can offer you a solution which will considerably reduce the storage space you require for your spare parts and, at the same time, ensure you can process several hundred picking lines per hour.

To ensure secure access to the parts stored, the tower is equipped with a name badge reader: based on their job, users will have access to one or several tower shelves when they badge in.

Do your parts need to be stored in a controlled environment?

The JUMPER automated storer offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

Would you like to enhance your order picking and shipping reliability?

The JUMPER dynamic storer stores several dozen thousand references of different volume-size thanks, in particular, to the myriad of set-ups and features proposed. This specificity makes the JUMPER vertical tower the perfect tool for order picking.

Combined with the G-STOCK WMS software and interfaced with your ERP, the tower lift can manage a high number of picking lines per hour and, at the same time, reduce shipping errors. Tower replenishment and picking are performed via a pick-to-light integrated in the tower and validations are made via an invisible curtain at the wave of a hand. Accuracy and swiftness ensure you significantly enhance customer satisfaction.

Is it important for you to optimize storage of small components?

The JUMPER storage tower is the perfect solution if you would like to optimize storage space for your raw materials, your semi-finished products or your parts to be shipped. A tower standing 14m² high can accept effective storage of over 200m² and may run to the full height of your premises.

The G-STOCK management software, combined with the JUMPER lift and interfaced with your ERP, offers you a real-time display of all the storage management, replenishment management, use-by date, serial number, batch number, etc. information you need.

The JUMPER includes a myriad of options tailor-designed for your activity (antistatic component management, area indicators for identifying your references, weighing scales, etc.).

The heterogeneity of maintenance parts as well as their occasionally sizeable load means proposing storage machines which are flexible, robust and secure. The JUMPER storage solution takes up to 500 kg effective load per shelf without the need for homogeneous load distribution on shelves (mechanically-welded structure). The rack and pinion assembly means there is no risk of accident (transmission belt breaking, etc.) and, at the same time, reduces the need for servicing. As such, you now have a storage solution which is perfectly tailored to even the most extreme environments.

Grasping hold of the mechanical devices may be made easier through the options for removing from drawers outside the tower: As such, you can collect your parts using a hoist, a jack or robotic arm.

Large quantities of spare parts in your garage often means having a large storage area available and putting together your kits can take you a considerable length of time. The various widths and depths of the tower's shelves mean we can offer you a solution which will considerably reduce the storage space you require for your spare parts and, at the same time, ensure you can process several hundred picking lines per hour.

To ensure secure access to the parts stored, the tower is equipped with a name badge reader: based on their job, users will have access to one or several tower shelves when they badge in.

The JUMPER automated storer offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

The JUMPER dynamic storer stores several dozen thousand references of different volume-size thanks, in particular, to the myriad of set-ups and features proposed. This specificity makes the JUMPER vertical tower the perfect tool for order picking.

Combined with the G-STOCK WMS software and interfaced with your ERP, the tower lift can manage a high number of picking lines per hour and, at the same time, reduce shipping errors. Tower replenishment and picking are performed via a pick-to-light integrated in the tower and validations are made via an invisible curtain at the wave of a hand. Accuracy and swiftness ensure you significantly enhance customer satisfaction.

The JUMPER storage tower is the perfect solution if you would like to optimize storage space for your raw materials, your semi-finished products or your parts to be shipped. A tower standing 14m² high can accept effective storage of over 200m² and may run to the full height of your premises.

The G-STOCK management software, combined with the JUMPER lift and interfaced with your ERP, offers you a real-time display of all the storage management, replenishment management, use-by date, serial number, batch number, etc. information you need.

The JUMPER includes a myriad of options tailor-designed for your activity (antistatic component management, area indicators for identifying your references, weighing scales, etc.).

Technical arguments

A high-quality product dedicated to your optimization

The JUMPER storage tower, designed for optimizing space and stock reliability, will also help you improve your equipment's in-service readiness.

Fonctionnalités

Rack and pinion assembly

The Jumper tower is equipped with a double rack enabling the mobile lifting platform to move. There is, therefore, no slackening as seen on technology using chains, cables or belts, which can incur substantial supplementary costs and trading losses related to the unavailability of the machine during servicing and periodic changes. This Jumper's technology also prevents any accidental breakage with other drive systems (chains, belts, cables, etc.). This assembly also ensures there is no imbalance on the shelves.

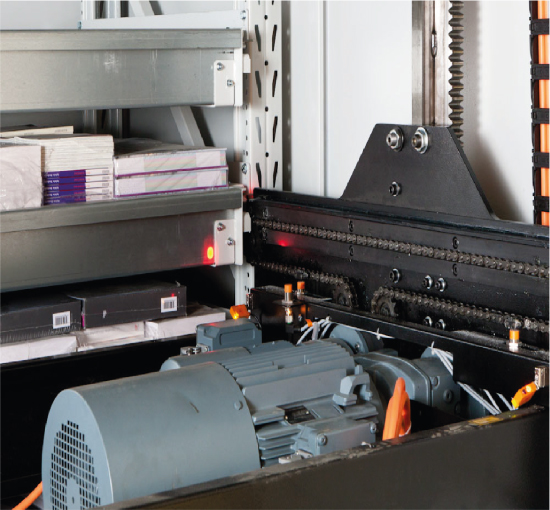

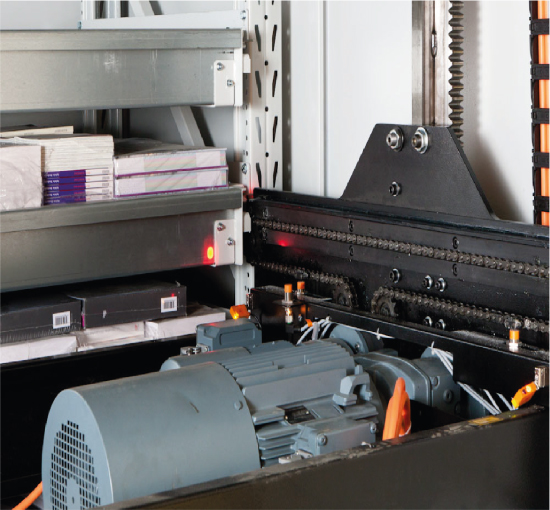

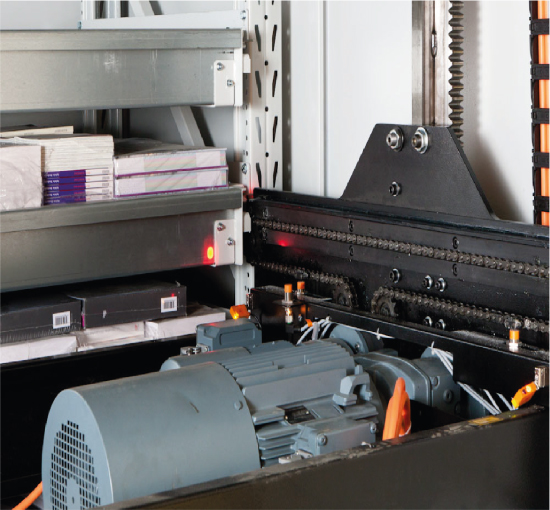

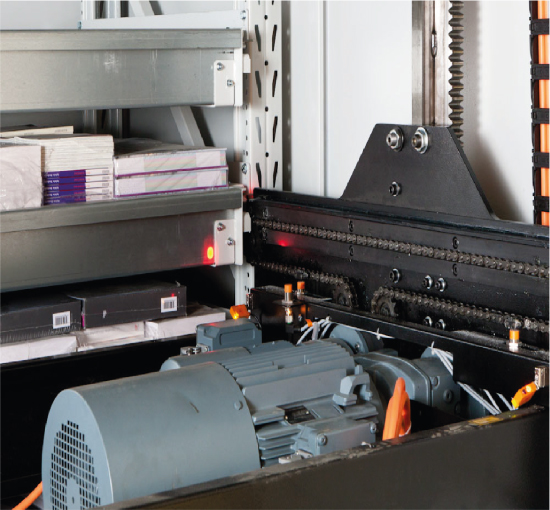

Double motorization for the mobile lifting platform

Double motorization for the mobile lifting platform

The mobile lifting platform is equipped with double motorization for 500 kg effective load and single motorization for 300 kg and, in both cases, is positioned on a rack and pinion drive. This double motorization enables the lifting platform to move up and down at flexible speeds initiated by the frequency-drives. Removal from drawers is also performed by two other motors which are also equipped with frequency-drives. There is, therefore, no thrust impact on the drawers and the references stored within are not disturbed. These motorizations offer optimally-reduced cycle time

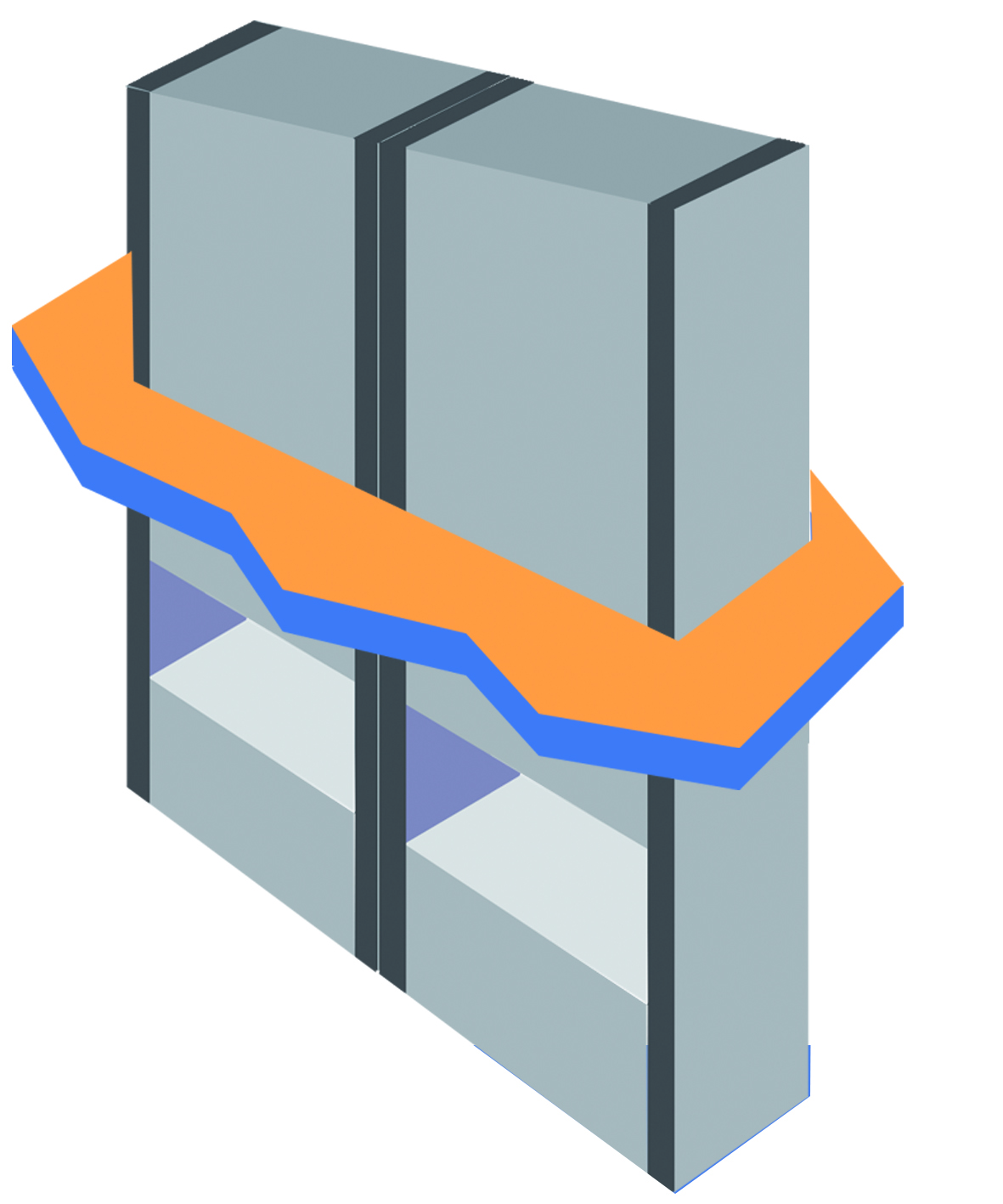

Tower structure

Tower structure

The structure comprises posts bearing the shelving rack load designed for an overall capacity of 60 tons. All the components of this structure are painted with fired epoxy paint which offers excellent long-wearing and premium class finish.

Mechanically-welded drawers

Mechanically-welded drawers

The drawers offer excellent strength through their 110 mm reinforced struts: drawer weakening issues are therefore prevented. They are designed to bear an unevenly spread-out effective load of 500 kg. There is therefore no need to spend time spreading the load evenly in the drawers.

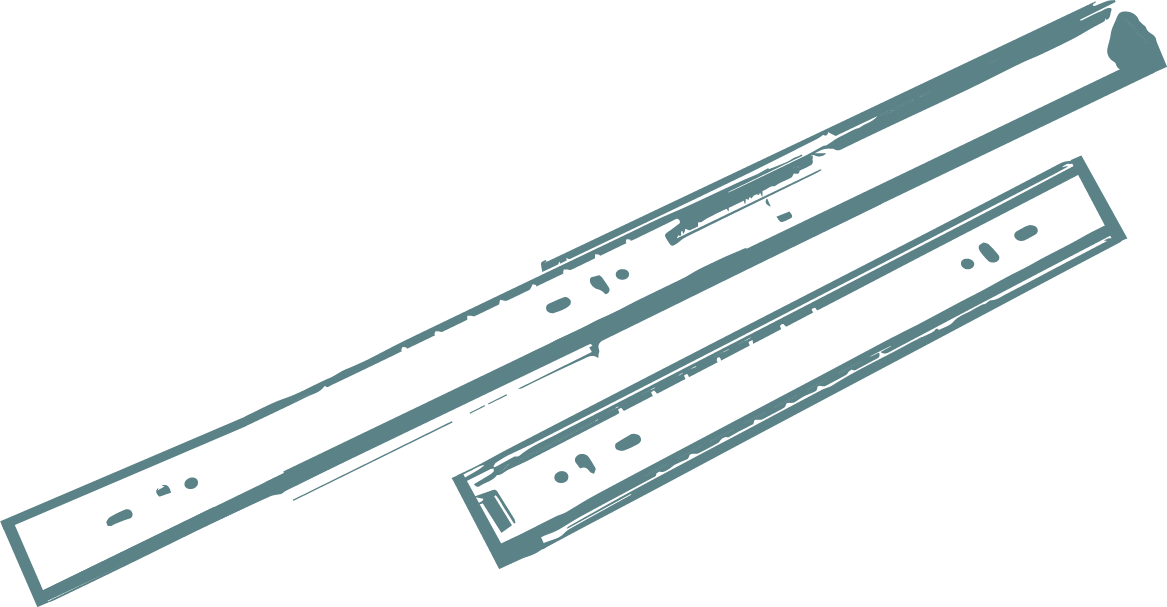

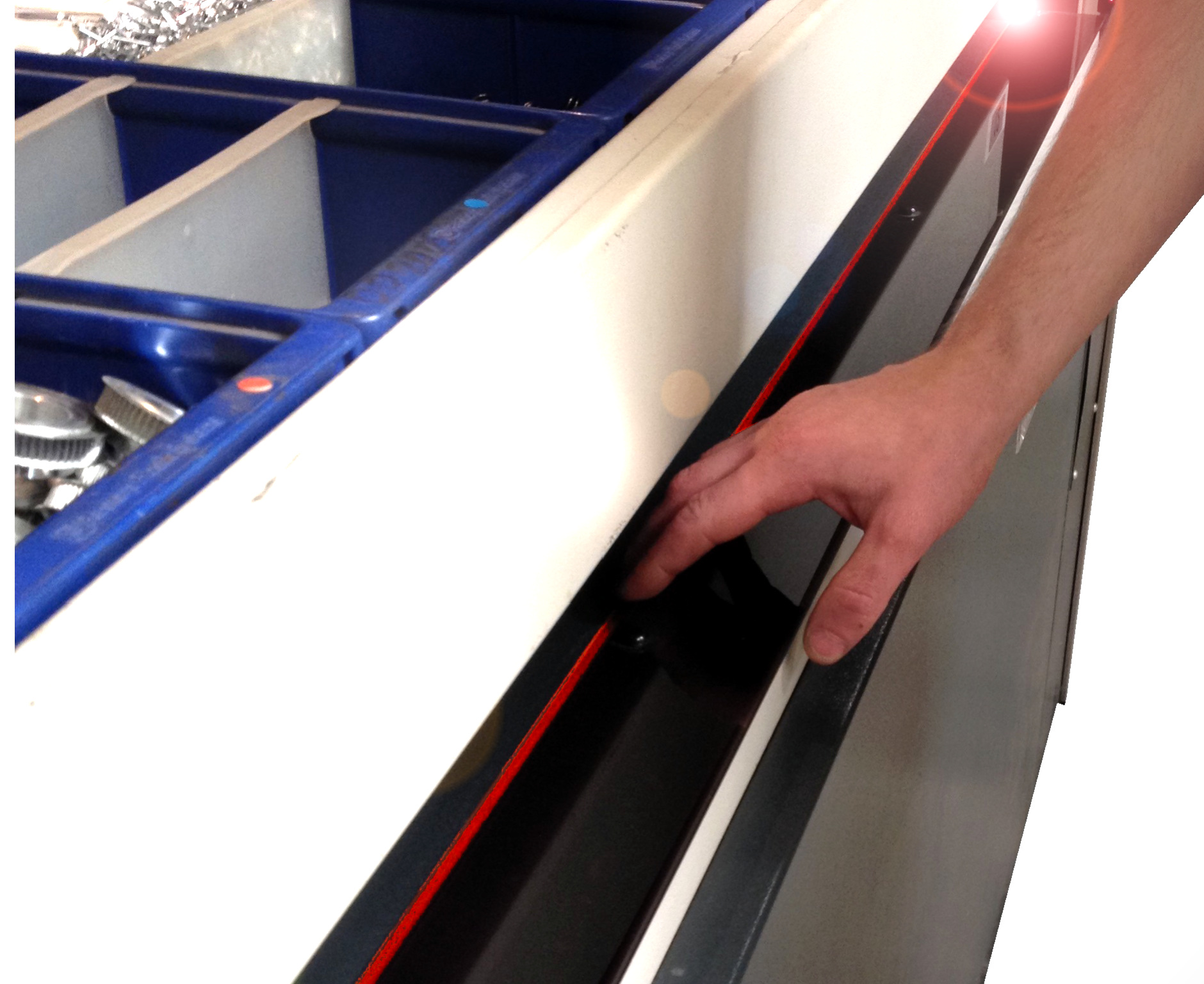

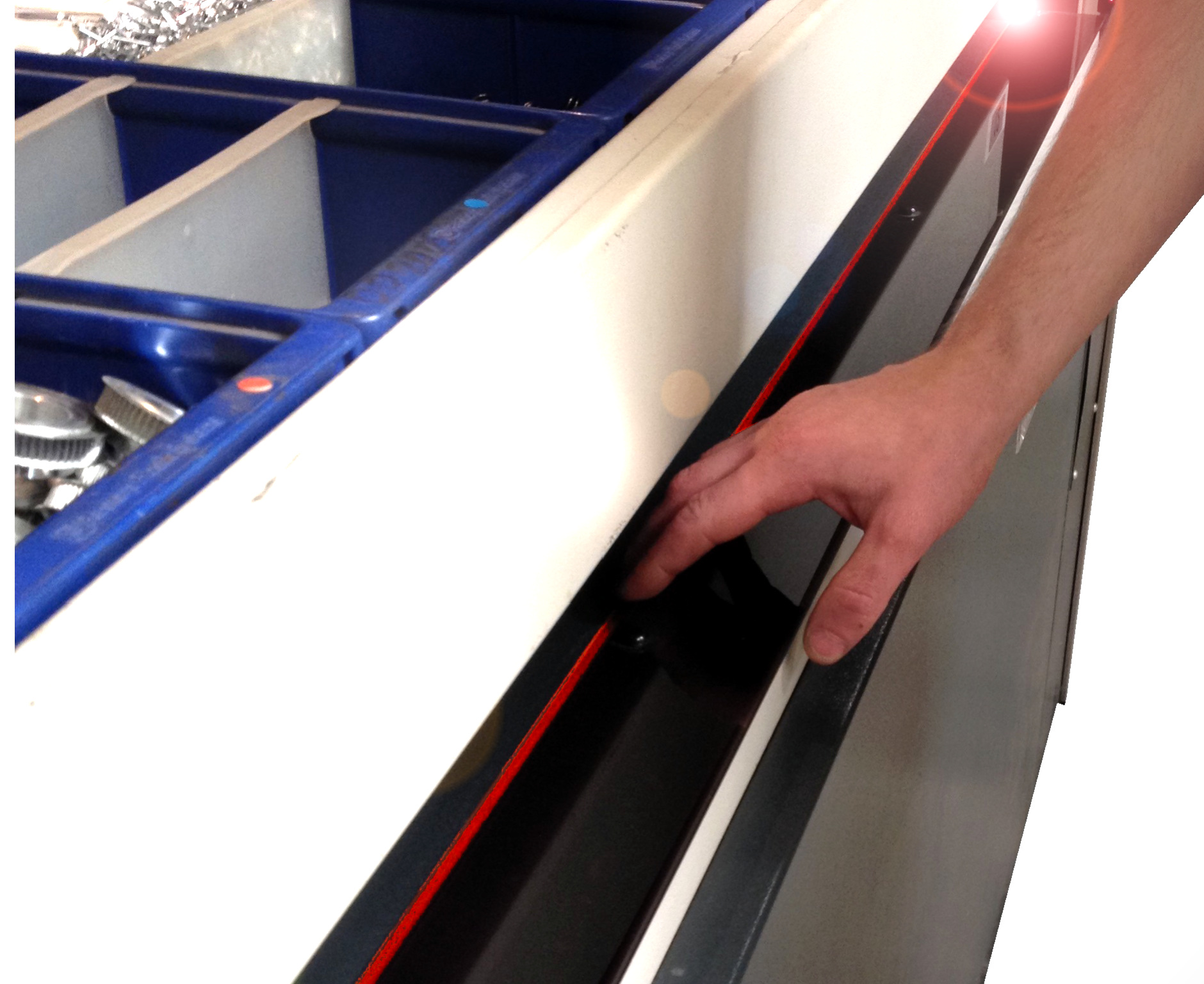

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

A high quality epoxy finish

Particular attention has been paid to the finish and aesthetics of the lift Jumper tower. The access bay is available in an expoxy or stainless steel version, the finishing panels are in structured epoxy and available in a wide range of colors.

Electrical equipment

All electrical equipment is as standard industrial supply. From motors, drives, to printed circuit boards, everything is simple in design, off-the-shelf (easy to service and to troubleshoot and to use). The automation technology used is a Siemens-compatible PLC.

Control panel

Control panel

The Jumper Tower is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Safety/Security sensors

Safety/Security sensors

As with all ELECTROCLASS storage solutions, the Jumper vertical tower benefits from the best performing safety and security systems. In addition to class 4 safety light curtains, a mechanical sensor detects overload on the workstation.

Servicing access

Servicing access

The entire automated and electrical part is located under the workstation. The control rack provides the best security for technicians entering the machine.

A high-quality product dedicated to your optimization

The JUMPER storage tower, designed for optimizing space and stock reliability, will also help you improve your equipment's in-service readiness.

Fonctionnalités

The Jumper tower is equipped with a double rack enabling the mobile lifting platform to move. There is, therefore, no slackening as seen on technology using chains, cables or belts, which can incur substantial supplementary costs and trading losses related to the unavailability of the machine during servicing and periodic changes. This Jumper's technology also prevents any accidental breakage with other drive systems (chains, belts, cables, etc.). This assembly also ensures there is no imbalance on the shelves.

Double motorization for the mobile lifting platform

Double motorization for the mobile lifting platform

The mobile lifting platform is equipped with double motorization for 500 kg effective load and single motorization for 300 kg and, in both cases, is positioned on a rack and pinion drive. This double motorization enables the lifting platform to move up and down at flexible speeds initiated by the frequency-drives. Removal from drawers is also performed by two other motors which are also equipped with frequency-drives. There is, therefore, no thrust impact on the drawers and the references stored within are not disturbed. These motorizations offer optimally-reduced cycle time

Tower structure

Tower structure

The structure comprises posts bearing the shelving rack load designed for an overall capacity of 60 tons. All the components of this structure are painted with fired epoxy paint which offers excellent long-wearing and premium class finish.

Mechanically-welded drawers

Mechanically-welded drawers

The drawers offer excellent strength through their 110 mm reinforced struts: drawer weakening issues are therefore prevented. They are designed to bear an unevenly spread-out effective load of 500 kg. There is therefore no need to spend time spreading the load evenly in the drawers. HDPE drawer guides (High-density polyethylene) The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

Particular attention has been paid to the finish and aesthetics of the lift Jumper tower. The access bay is available in an expoxy or stainless steel version, the finishing panels are in structured epoxy and available in a wide range of colors.

All electrical equipment is as standard industrial supply. From motors, drives, to printed circuit boards, everything is simple in design, off-the-shelf (easy to service and to troubleshoot and to use). The automation technology used is a Siemens-compatible PLC.

Control panel

Control panel

The Jumper Tower is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Safety/Security sensors

Safety/Security sensors

As with all ELECTROCLASS storage solutions, the Jumper vertical tower benefits from the best performing safety and security systems. In addition to class 4 safety light curtains, a mechanical sensor detects overload on the workstation.

Servicing access

Servicing access

The entire automated and electrical part is located under the workstation. The control rack provides the best security for technicians entering the machine.

Have you got a specific project?

We'd be delighted to hear from you!

Range

Options

The "area indicators" option offers a set of configurable diodes with 20 mm spacing. These are positioned in the lookup table and, using the G-STOCK management software , allow you to identify the exact location of the references to be taken out.

The corrugated iron curtain is replaced by an electric curtain, worked by a lock-with-key system or by G-STOCK WMS whenever it is necessary to secure access to specific references. This option is useful for parts which must be stored in controlled-temperature or constant-atmosphere environments.

We propose secure access to the Jumper lift via a badge reader (adaptable to all badging technologies).

A safety light curtain, under the lookup table, enables you to validate the "Enter" key with a flick of the hand.

Storage towers can be equipped with ventilation systems (CMV), with systems for ensuring temperature and humidity remain constant as well as a cooling unit, etc. They can also be equipped with fire detection and gas injection systems.

In order to facilitate the handling of heavy products, the Titan can be provided with dedicated arrangements such as bins on rolled sections or multidirectional bearing service

The oak table offers a high quality finish to the viewing bay.

With their 50 mm spacing, Jumper drawers are designed in galvanized sheet metal and offer the opportunity to compartmentalize a drawer. These features, linked to the area indicators are used to organize the contents of drawers optimally

The weighing scale option should be integrated whenever the load borne by the Jumper drawers needs to be monitored. The weight is displayed on the touch screen. Weighing scales may also be used with roller-led chassis for manual removal with stabilizing legs or on a trolley.

The Jumper may also be equipped with the antistatic option. Owing to its design (spars and shelves in galvanized steel), the drawers dissipate static electricity via a set of metallic brushes which grounds them. By touching the front spar of a drawer, the user will no longer be electrically charged and, as such, can handle sensitive equipment safely.

Jumpers can also be equipped with an automatic extractor. You can then use a bridge crane or a hoist to remove heavy parts from the drawers. The invisible curtain is in this case on the extractor station.

The Jumper can be equipped with a collapsible manual extractor whenever you need to use a bridge crane or a hoist to remove heavy parts.

Jumpers can be equipped with double front/rear viewing. This allows two people to take references from two separate drawers at the same time. The mobile lifting platform will move to one side then to the other. This requires double identification for the references or the locations.

Jumpers can be equipped with double high/low viewing. This allows two people to take references from two separate drawers at the same time. The mobile lifting platform will move to one level then to another.

Have you got a specific project?

We'd be delighted to hear from you!

Have you got a specific project?

We'd be delighted to hear from you!

Optimize space and time with the Jumper storage tower!

The fast and powerful JUMPER tower is the perfect solution for automating the storage of your heavy, heterogeneous-volume components so that you can:

- Optimize your storage space (up to 91% less space occupied)

- Reduce risk of civilian incidents

- Secure your products and reduce picking errors

- Simplify your stock management through our GSTOCK WMS software

- Increase your productivity

In storage structure which can take up to 60 tons, the mobile lifting platform moves vertically between the two storage volumes and removes the drawers to place them on the viewing station, designed to prevent musculoskeletal disorders and injuries.

The fast and powerful JUMPER tower is the perfect solution for automating the storage of your heavy, heterogeneous-volume components so that you can:

- Optimize your storage space (up to 91% less space occupied)

- Reduce risk of civilian incidents

- Secure your products and reduce picking errors

- Simplify your stock management through our GSTOCK WMS software

- Increase your productivity

In storage structure which can take up to 60 tons, the mobile lifting platform moves vertically between the two storage volumes and removes the drawers to place them on the viewing station, designed to prevent musculoskeletal disorders and injuries.

Customer issues

Would you like to automate your maintenance parts store?

The heterogeneity of maintenance parts as well as their occasionally sizeable load means proposing storage machines which are flexible, robust and secure. The JUMPER storage solution takes up to 500 kg effective load per shelf without the need for homogeneous load distribution on shelves (mechanically-welded structure). The rack and pinion assembly means there is no risk of accident (transmission belt breaking, etc.) and, at the same time, reduces the need for servicing. As such, you now have a storage solution which is perfectly tailored to even the most extreme environments.

Grasping hold of the mechanical devices may be made easier through the options for removing from drawers outside the tower: As such, you can collect your parts using a hoist, a jack or robotic arm.

Would you like to secure the spare part management for all your vehicles?

Large quantities of spare parts in your garage often means having a large storage area available and putting together your kits can take you a considerable length of time. The various widths and depths of the tower's shelves mean we can offer you a solution which will considerably reduce the storage space you require for your spare parts and, at the same time, ensure you can process several hundred picking lines per hour.

To ensure secure access to the parts stored, the tower is equipped with a name badge reader: based on their job, users will have access to one or several tower shelves when they badge in.

Do your parts need to be stored in a controlled environment?

The JUMPER automated storer offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

Would you like to enhance your order picking and shipping reliability?

The JUMPER dynamic storer stores several dozen thousand references of different volume-size thanks, in particular, to the myriad of set-ups and features proposed. This specificity makes the JUMPER vertical tower the perfect tool for order picking.

Combined with the G-STOCK WMS software and interfaced with your ERP, the tower lift can manage a high number of picking lines per hour and, at the same time, reduce shipping errors. Tower replenishment and picking are performed via a pick-to-light integrated in the tower and validations are made via an invisible curtain at the wave of a hand. Accuracy and swiftness ensure you significantly enhance customer satisfaction.

Is it important for you to optimize storage of small components?

The JUMPER storage tower is the perfect solution if you would like to optimize storage space for your raw materials, your semi-finished products or your parts to be shipped. A tower standing 14m² high can accept effective storage of over 200m² and may run to the full height of your premises.

The G-STOCK management software, combined with the JUMPER lift and interfaced with your ERP, offers you a real-time display of all the storage management, replenishment management, use-by date, serial number, batch number, etc. information you need.

The JUMPER includes a myriad of options tailor-designed for your activity (antistatic component management, area indicators for identifying your references, weighing scales, etc.).

The heterogeneity of maintenance parts as well as their occasionally sizeable load means proposing storage machines which are flexible, robust and secure. The JUMPER storage solution takes up to 500 kg effective load per shelf without the need for homogeneous load distribution on shelves (mechanically-welded structure). The rack and pinion assembly means there is no risk of accident (transmission belt breaking, etc.) and, at the same time, reduces the need for servicing. As such, you now have a storage solution which is perfectly tailored to even the most extreme environments.

Grasping hold of the mechanical devices may be made easier through the options for removing from drawers outside the tower: As such, you can collect your parts using a hoist, a jack or robotic arm.

Large quantities of spare parts in your garage often means having a large storage area available and putting together your kits can take you a considerable length of time. The various widths and depths of the tower's shelves mean we can offer you a solution which will considerably reduce the storage space you require for your spare parts and, at the same time, ensure you can process several hundred picking lines per hour.

To ensure secure access to the parts stored, the tower is equipped with a name badge reader: based on their job, users will have access to one or several tower shelves when they badge in.

The JUMPER automated storer offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

The JUMPER dynamic storer stores several dozen thousand references of different volume-size thanks, in particular, to the myriad of set-ups and features proposed. This specificity makes the JUMPER vertical tower the perfect tool for order picking.

Combined with the G-STOCK WMS software and interfaced with your ERP, the tower lift can manage a high number of picking lines per hour and, at the same time, reduce shipping errors. Tower replenishment and picking are performed via a pick-to-light integrated in the tower and validations are made via an invisible curtain at the wave of a hand. Accuracy and swiftness ensure you significantly enhance customer satisfaction.

The JUMPER storage tower is the perfect solution if you would like to optimize storage space for your raw materials, your semi-finished products or your parts to be shipped. A tower standing 14m² high can accept effective storage of over 200m² and may run to the full height of your premises.

The G-STOCK management software, combined with the JUMPER lift and interfaced with your ERP, offers you a real-time display of all the storage management, replenishment management, use-by date, serial number, batch number, etc. information you need.

The JUMPER includes a myriad of options tailor-designed for your activity (antistatic component management, area indicators for identifying your references, weighing scales, etc.).

Technical arguments

A high-quality product dedicated to your optimization

The JUMPER storage tower, designed for optimizing space and stock reliability, will also help you improve your equipment's in-service readiness.

Fonctionnalités

Rack and pinion assembly

The Jumper tower is equipped with a double rack enabling the mobile lifting platform to move. There is, therefore, no slackening as seen on technology using chains, cables or belts, which can incur substantial supplementary costs and trading losses related to the unavailability of the machine during servicing and periodic changes. This Jumper's technology also prevents any accidental breakage with other drive systems (chains, belts, cables, etc.). This assembly also ensures there is no imbalance on the shelves.

Double motorization for the mobile lifting platform

Double motorization for the mobile lifting platform

The mobile lifting platform is equipped with double motorization for 500 kg effective load and single motorization for 300 kg and, in both cases, is positioned on a rack and pinion drive. This double motorization enables the lifting platform to move up and down at flexible speeds initiated by the frequency-drives. Removal from drawers is also performed by two other motors which are also equipped with frequency-drives. There is, therefore, no thrust impact on the drawers and the references stored within are not disturbed. These motorizations offer optimally-reduced cycle time

Tower structure

Tower structure

The structure comprises posts bearing the shelving rack load designed for an overall capacity of 60 tons. All the components of this structure are painted with fired epoxy paint which offers excellent long-wearing and premium class finish.

Mechanically-welded drawers

Mechanically-welded drawers

The drawers offer excellent strength through their 110 mm reinforced struts: drawer weakening issues are therefore prevented. They are designed to bear an unevenly spread-out effective load of 500 kg. There is therefore no need to spend time spreading the load evenly in the drawers.

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

A high quality epoxy finish

Particular attention has been paid to the finish and aesthetics of the lift Jumper tower. The access bay is available in an expoxy or stainless steel version, the finishing panels are in structured epoxy and available in a wide range of colors.

Electrical equipment

All electrical equipment is as standard industrial supply. From motors, drives, to printed circuit boards, everything is simple in design, off-the-shelf (easy to service and to troubleshoot and to use). The automation technology used is a Siemens-compatible PLC.

Control panel

Control panel

The Jumper Tower is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Safety/Security sensors

Safety/Security sensors

As with all ELECTROCLASS storage solutions, the Jumper vertical tower benefits from the best performing safety and security systems. In addition to class 4 safety light curtains, a mechanical sensor detects overload on the workstation.

Servicing access

Servicing access

The entire automated and electrical part is located under the workstation. The control rack provides the best security for technicians entering the machine.

A high-quality product dedicated to your optimization

The JUMPER storage tower, designed for optimizing space and stock reliability, will also help you improve your equipment's in-service readiness.

Fonctionnalités

The Jumper tower is equipped with a double rack enabling the mobile lifting platform to move. There is, therefore, no slackening as seen on technology using chains, cables or belts, which can incur substantial supplementary costs and trading losses related to the unavailability of the machine during servicing and periodic changes. This Jumper's technology also prevents any accidental breakage with other drive systems (chains, belts, cables, etc.). This assembly also ensures there is no imbalance on the shelves.

Double motorization for the mobile lifting platform

Double motorization for the mobile lifting platform

The mobile lifting platform is equipped with double motorization for 500 kg effective load and single motorization for 300 kg and, in both cases, is positioned on a rack and pinion drive. This double motorization enables the lifting platform to move up and down at flexible speeds initiated by the frequency-drives. Removal from drawers is also performed by two other motors which are also equipped with frequency-drives. There is, therefore, no thrust impact on the drawers and the references stored within are not disturbed. These motorizations offer optimally-reduced cycle time

Tower structure

Tower structure

The structure comprises posts bearing the shelving rack load designed for an overall capacity of 60 tons. All the components of this structure are painted with fired epoxy paint which offers excellent long-wearing and premium class finish.

Mechanically-welded drawers

Mechanically-welded drawers

The drawers offer excellent strength through their 110 mm reinforced struts: drawer weakening issues are therefore prevented. They are designed to bear an unevenly spread-out effective load of 500 kg. There is therefore no need to spend time spreading the load evenly in the drawers. HDPE drawer guides (High-density polyethylene) The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

Particular attention has been paid to the finish and aesthetics of the lift Jumper tower. The access bay is available in an expoxy or stainless steel version, the finishing panels are in structured epoxy and available in a wide range of colors.

All electrical equipment is as standard industrial supply. From motors, drives, to printed circuit boards, everything is simple in design, off-the-shelf (easy to service and to troubleshoot and to use). The automation technology used is a Siemens-compatible PLC.

Control panel

Control panel

The Jumper Tower is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Safety/Security sensors

Safety/Security sensors

As with all ELECTROCLASS storage solutions, the Jumper vertical tower benefits from the best performing safety and security systems. In addition to class 4 safety light curtains, a mechanical sensor detects overload on the workstation.

Servicing access

Servicing access

The entire automated and electrical part is located under the workstation. The control rack provides the best security for technicians entering the machine.

Have you got a specific project?

We'd be delighted to hear from you!

Range

Options

The "area indicators" option offers a set of configurable diodes with 20 mm spacing. These are positioned in the lookup table and, using the G-STOCK management software , allow you to identify the exact location of the references to be taken out.

The corrugated iron curtain is replaced by an electric curtain, worked by a lock-with-key system or by G-STOCK WMS whenever it is necessary to secure access to specific references. This option is useful for parts which must be stored in controlled-temperature or constant-atmosphere environments.

We propose secure access to the Jumper lift via a badge reader (adaptable to all badging technologies).

A safety light curtain, under the lookup table, enables you to validate the "Enter" key with a flick of the hand.

Storage towers can be equipped with ventilation systems (CMV), with systems for ensuring temperature and humidity remain constant as well as a cooling unit, etc. They can also be equipped with fire detection and gas injection systems.

In order to facilitate the handling of heavy products, the Titan can be provided with dedicated arrangements such as bins on rolled sections or multidirectional bearing service

The oak table offers a high quality finish to the viewing bay.

With their 50 mm spacing, Jumper drawers are designed in galvanized sheet metal and offer the opportunity to compartmentalize a drawer. These features, linked to the area indicators are used to organize the contents of drawers optimally

The weighing scale option should be integrated whenever the load borne by the Jumper drawers needs to be monitored. The weight is displayed on the touch screen. Weighing scales may also be used with roller-led chassis for manual removal with stabilizing legs or on a trolley.

The Jumper may also be equipped with the antistatic option. Owing to its design (spars and shelves in galvanized steel), the drawers dissipate static electricity via a set of metallic brushes which grounds them. By touching the front spar of a drawer, the user will no longer be electrically charged and, as such, can handle sensitive equipment safely.

Jumpers can also be equipped with an automatic extractor. You can then use a bridge crane or a hoist to remove heavy parts from the drawers. The invisible curtain is in this case on the extractor station.

The Jumper can be equipped with a collapsible manual extractor whenever you need to use a bridge crane or a hoist to remove heavy parts.

Jumpers can be equipped with double front/rear viewing. This allows two people to take references from two separate drawers at the same time. The mobile lifting platform will move to one side then to the other. This requires double identification for the references or the locations.

Jumpers can be equipped with double high/low viewing. This allows two people to take references from two separate drawers at the same time. The mobile lifting platform will move to one level then to another.

Have you got a specific project?

We'd be delighted to hear from you!

Have you got a specific project?

We'd be delighted to hear from you!