Breadcrumbs

SILO ASRS

Make your warehouse smart thanks to the Silo ASRS !

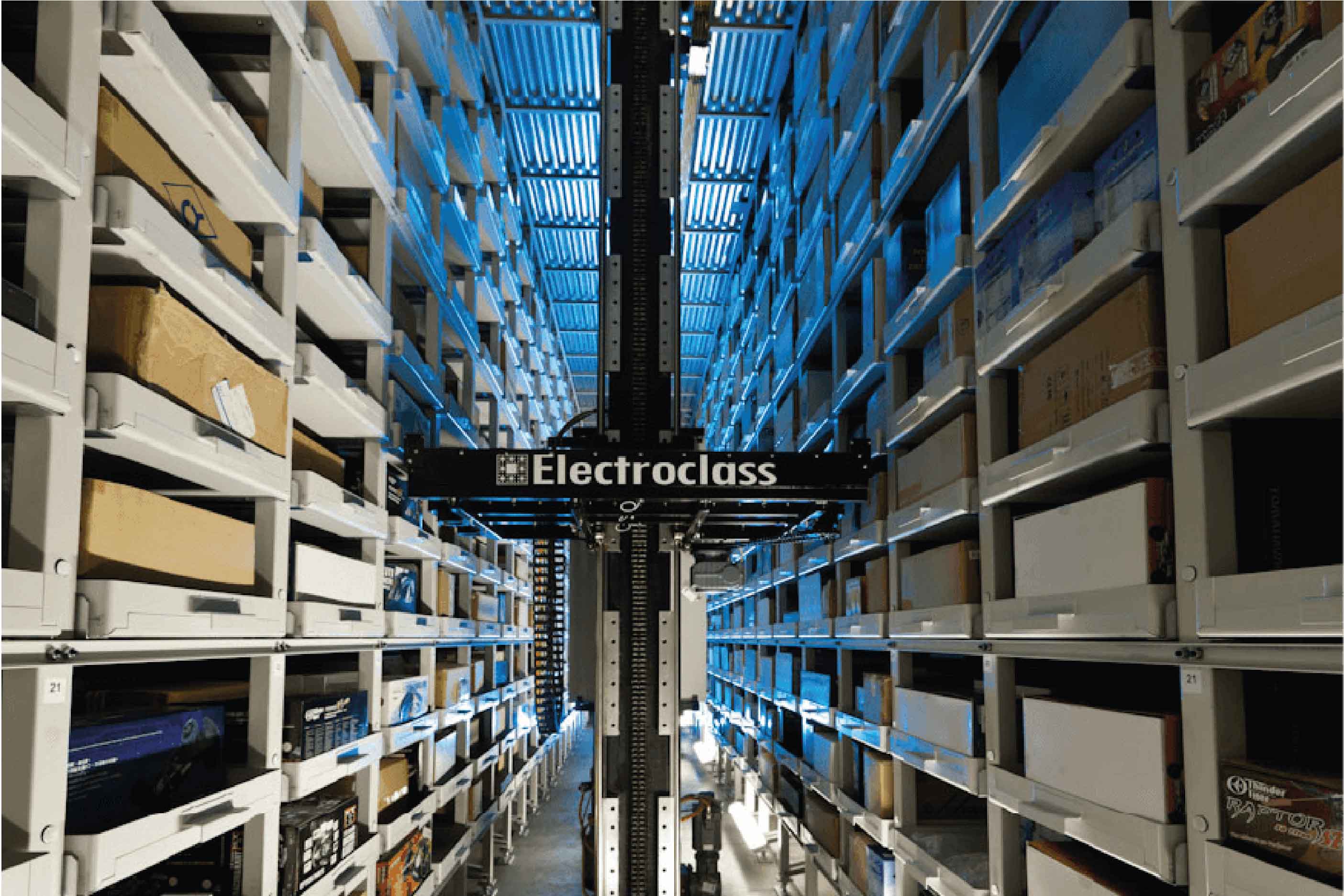

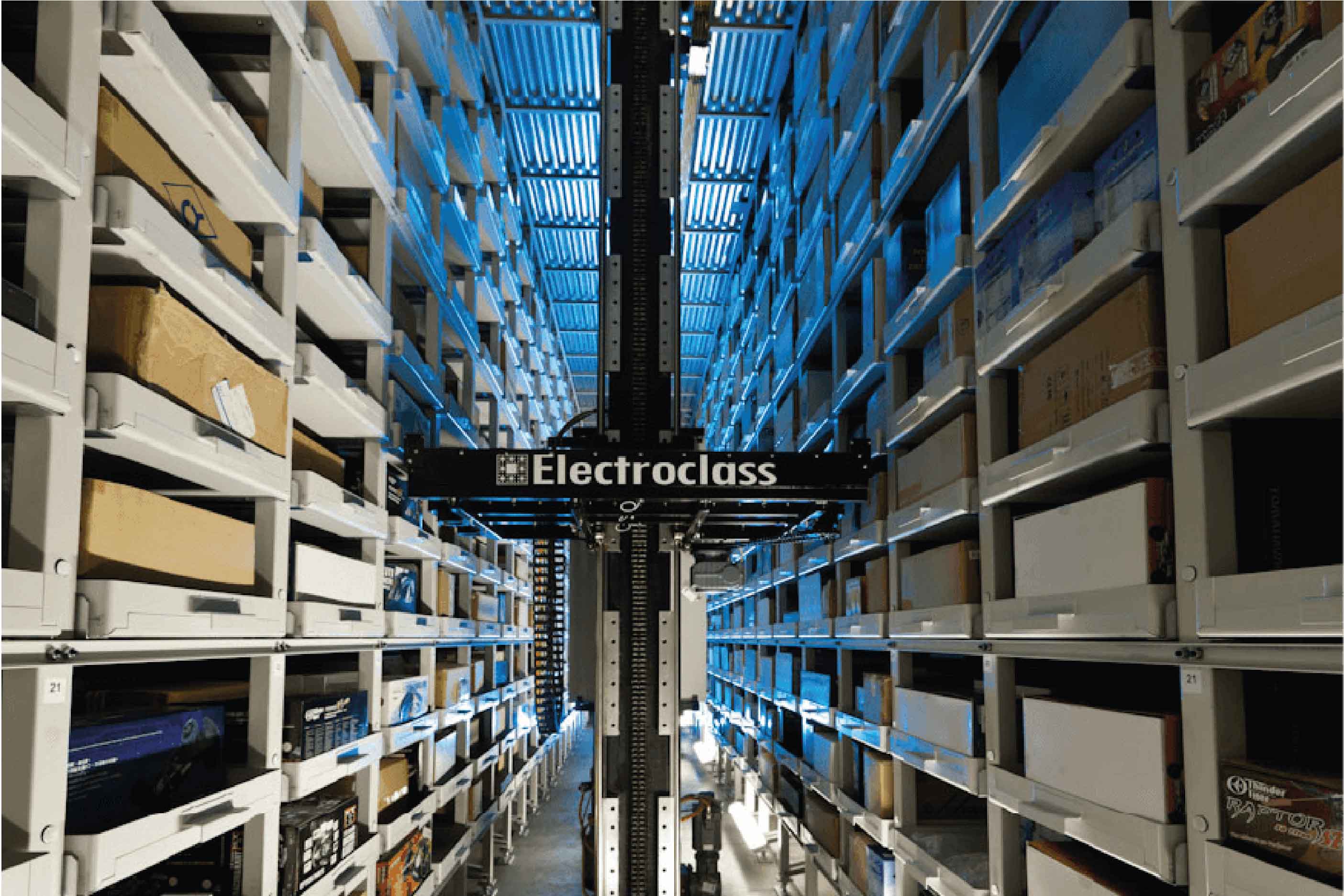

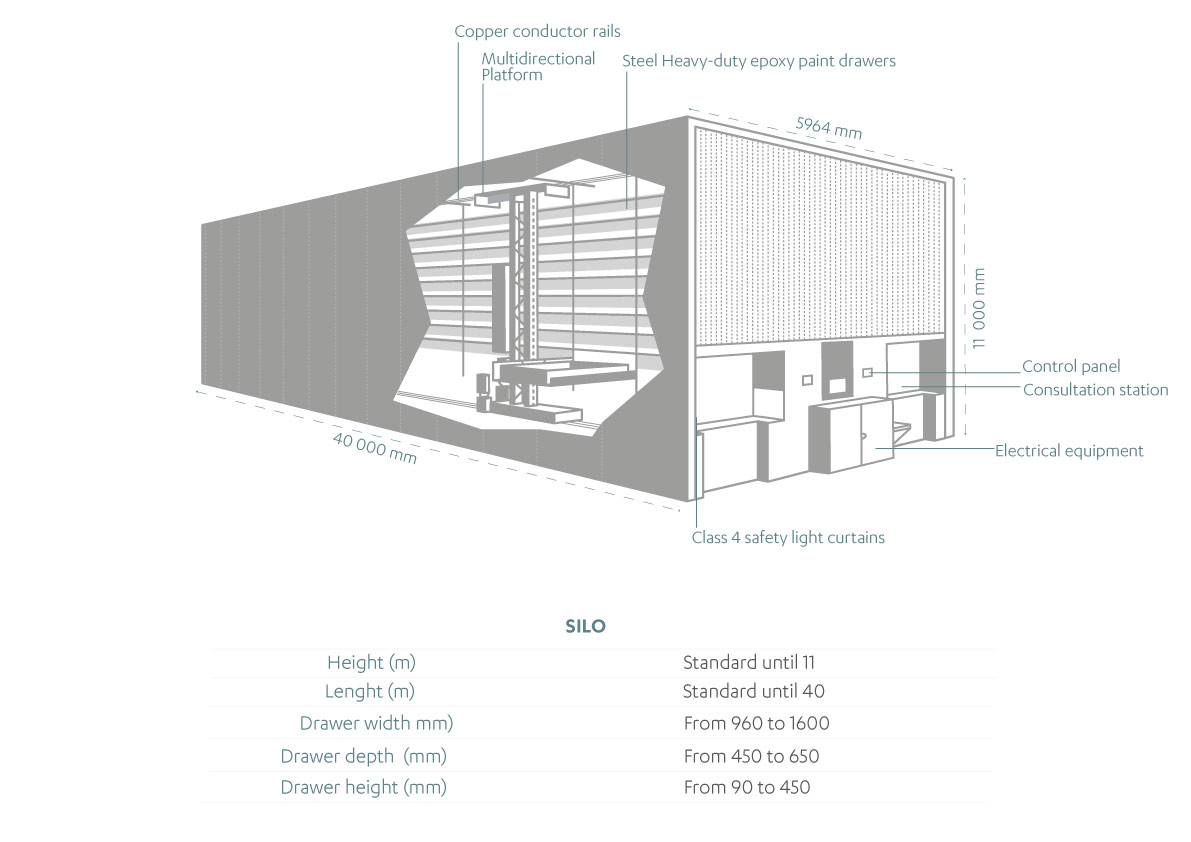

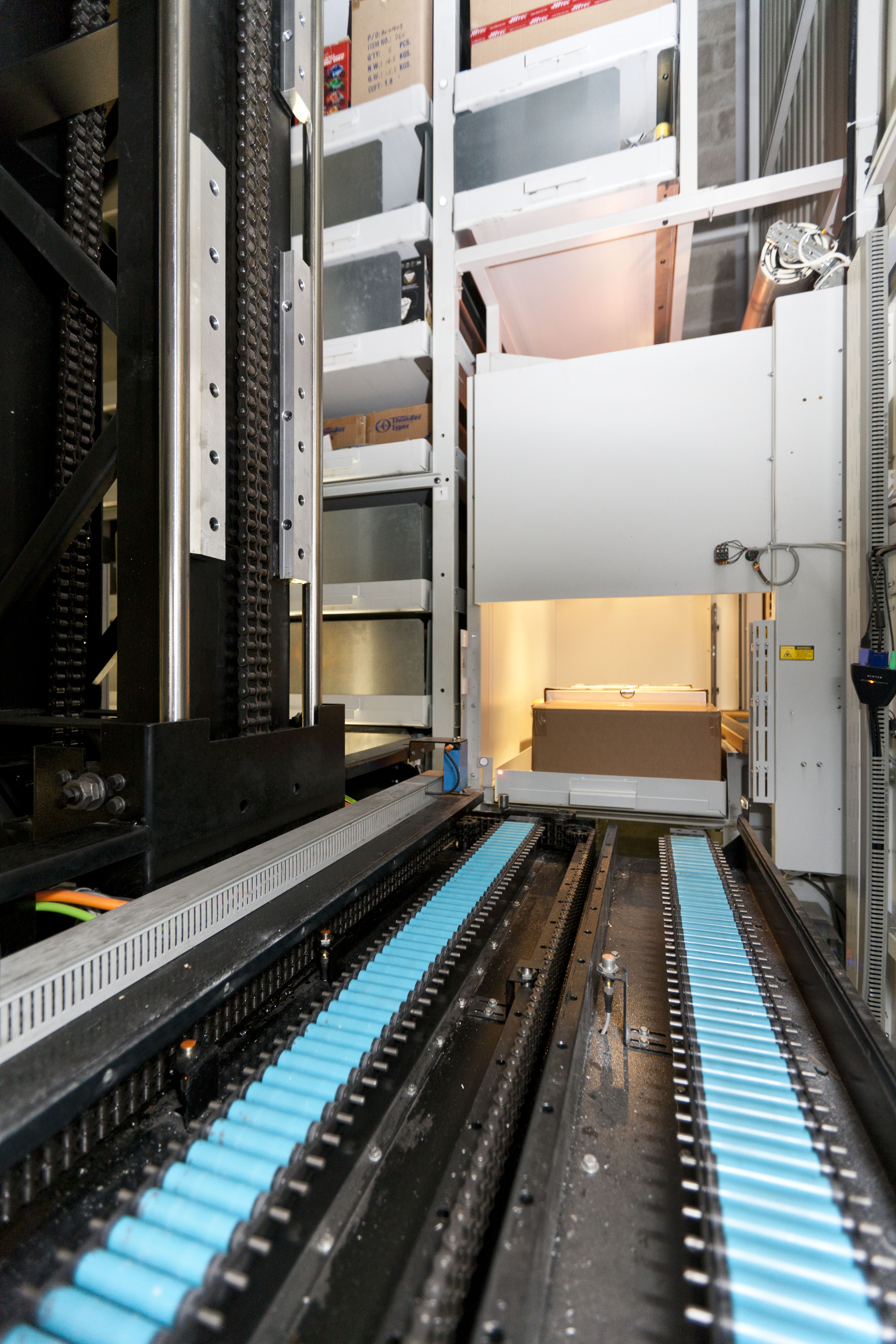

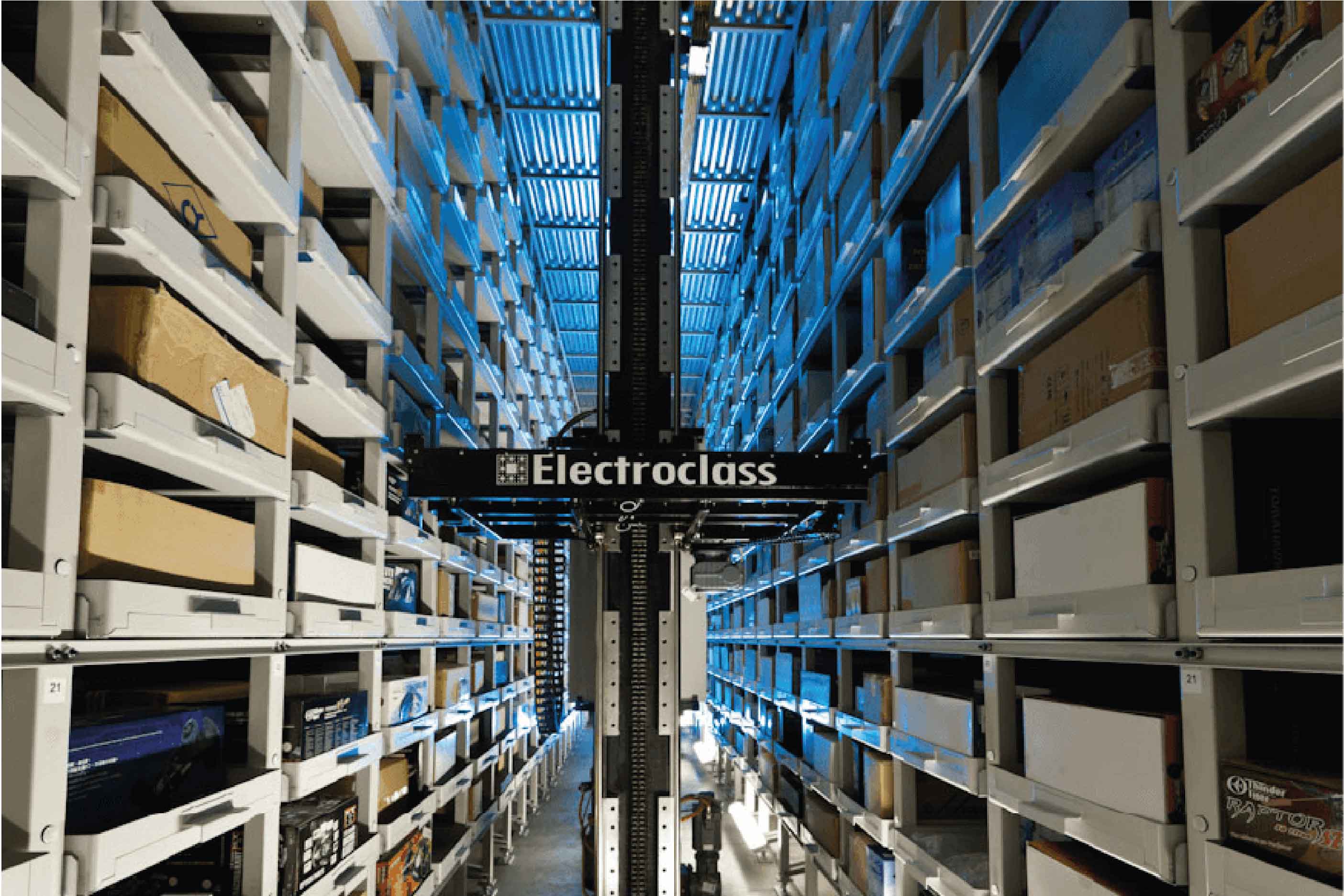

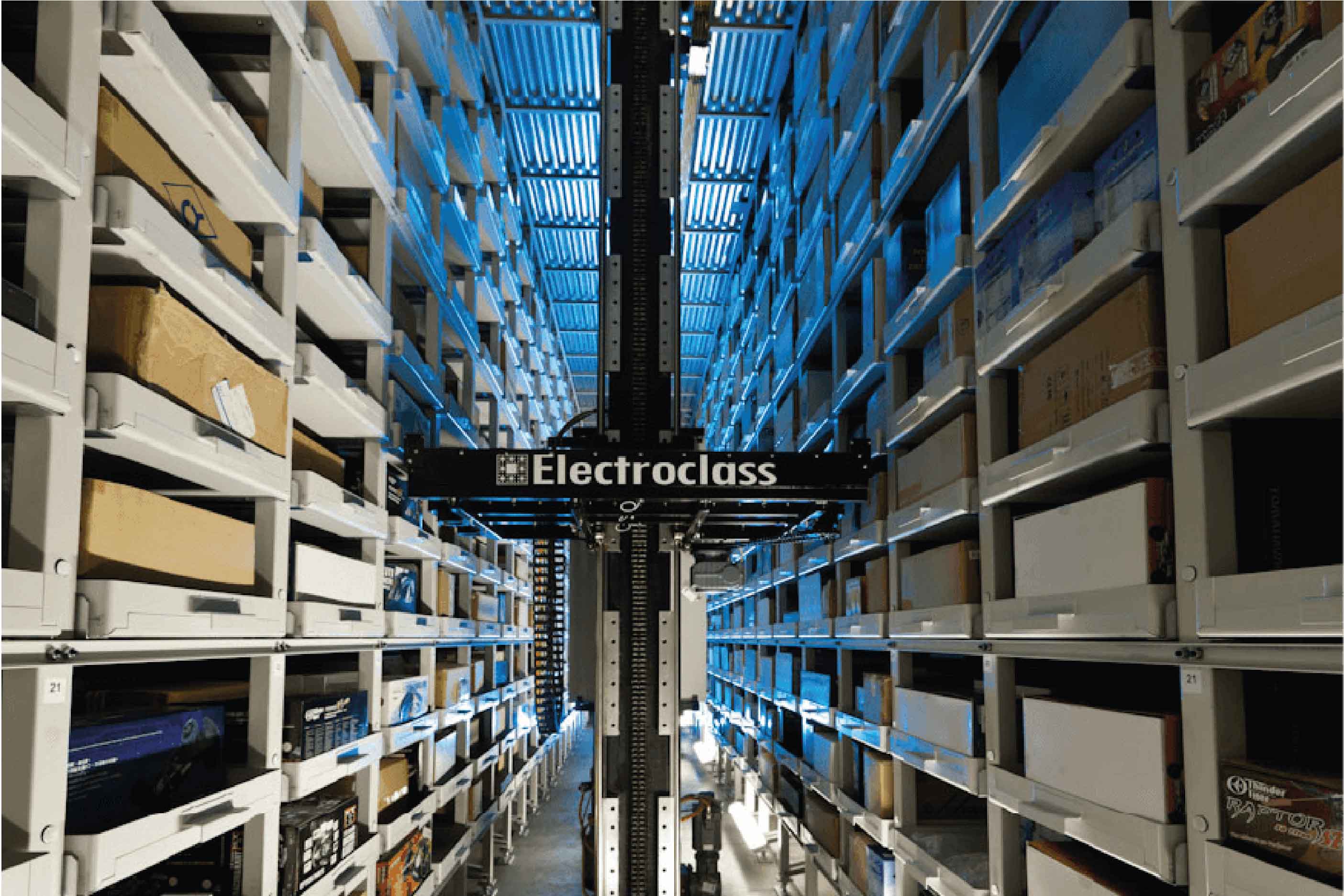

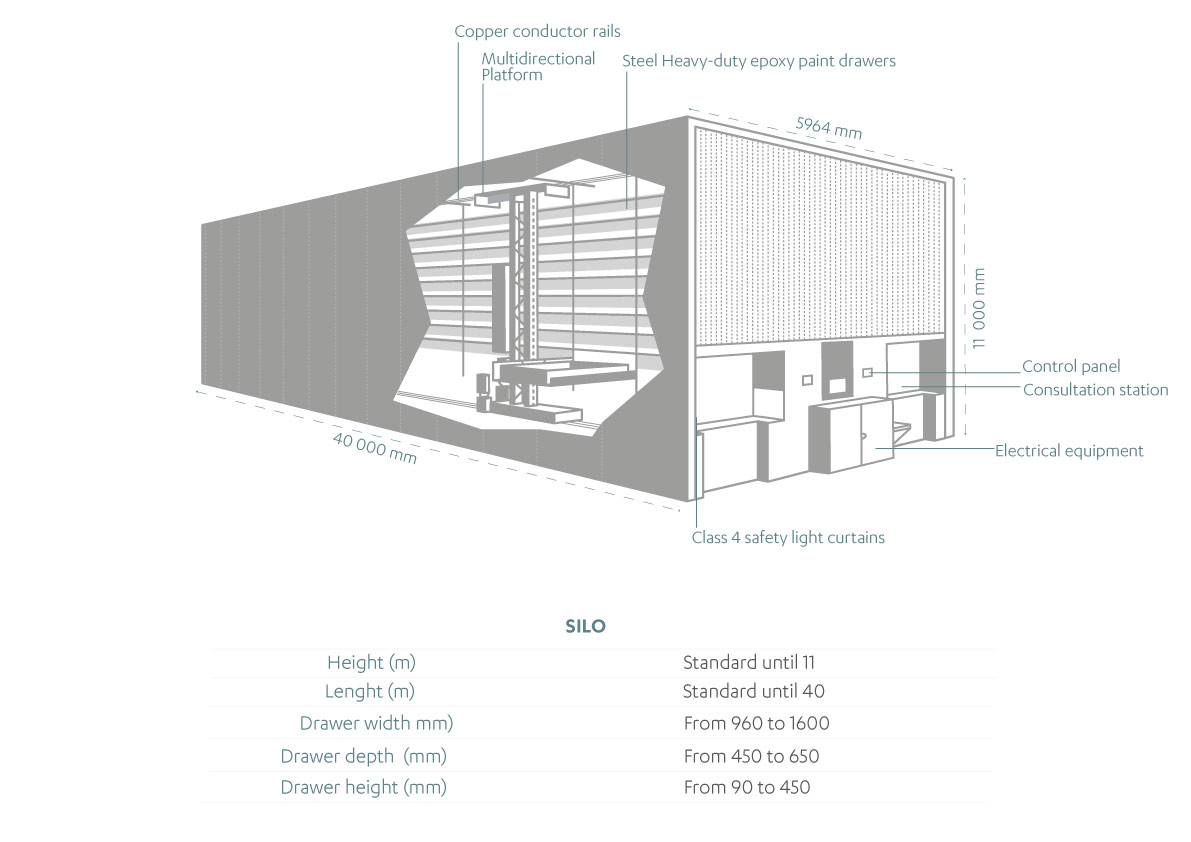

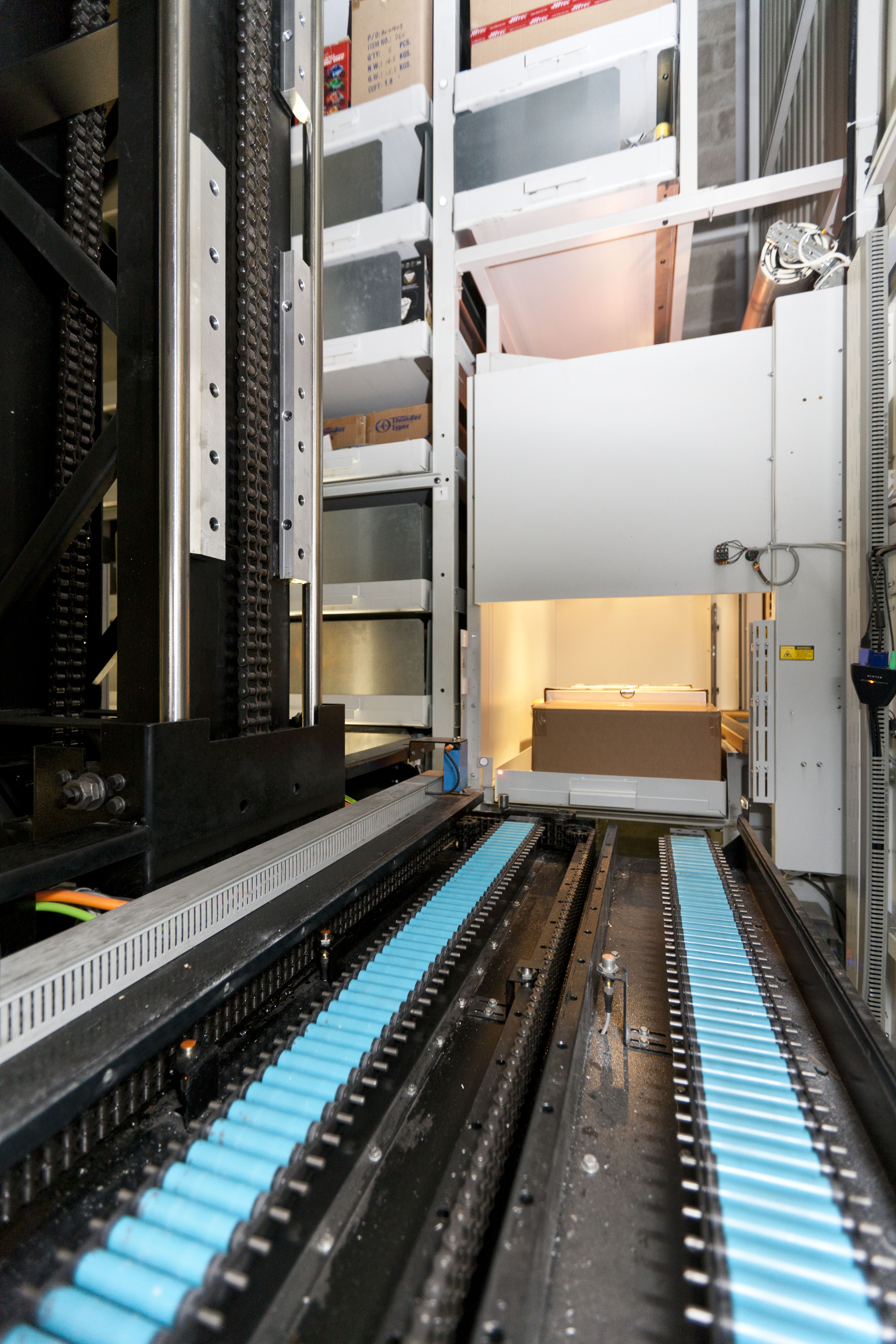

The SILO ASRS automated storer, consisting of two racking systems and an automated trolley and crane system moving along the central aisle: offers you short access times, optimal storage space management, high handling throughput as well as optimal access to small and large volume-size supplies.

The Silo ASRS stores all types of parts and/or boxes quickly, flexibly and reliably, so that you can:

- optimize your storage space

- secure your products

- simplify your stock management through our G-STOCK WMS software

- increase your productivity

The SILO ASRS automated storer, consisting of two racking systems and an automated trolley and crane system moving along the central aisle: offers you short access times, optimal storage space management, high handling throughput as well as optimal access to small and large volume-size supplies.

The Silo ASRS stores all types of parts and/or boxes quickly, flexibly and reliably, so that you can:

- optimize your storage space

- secure your products

- simplify your stock management through our G-STOCK WMS software

- increase your productivity

On-site issues

Do you need to manage your maintenance parts more optimally?

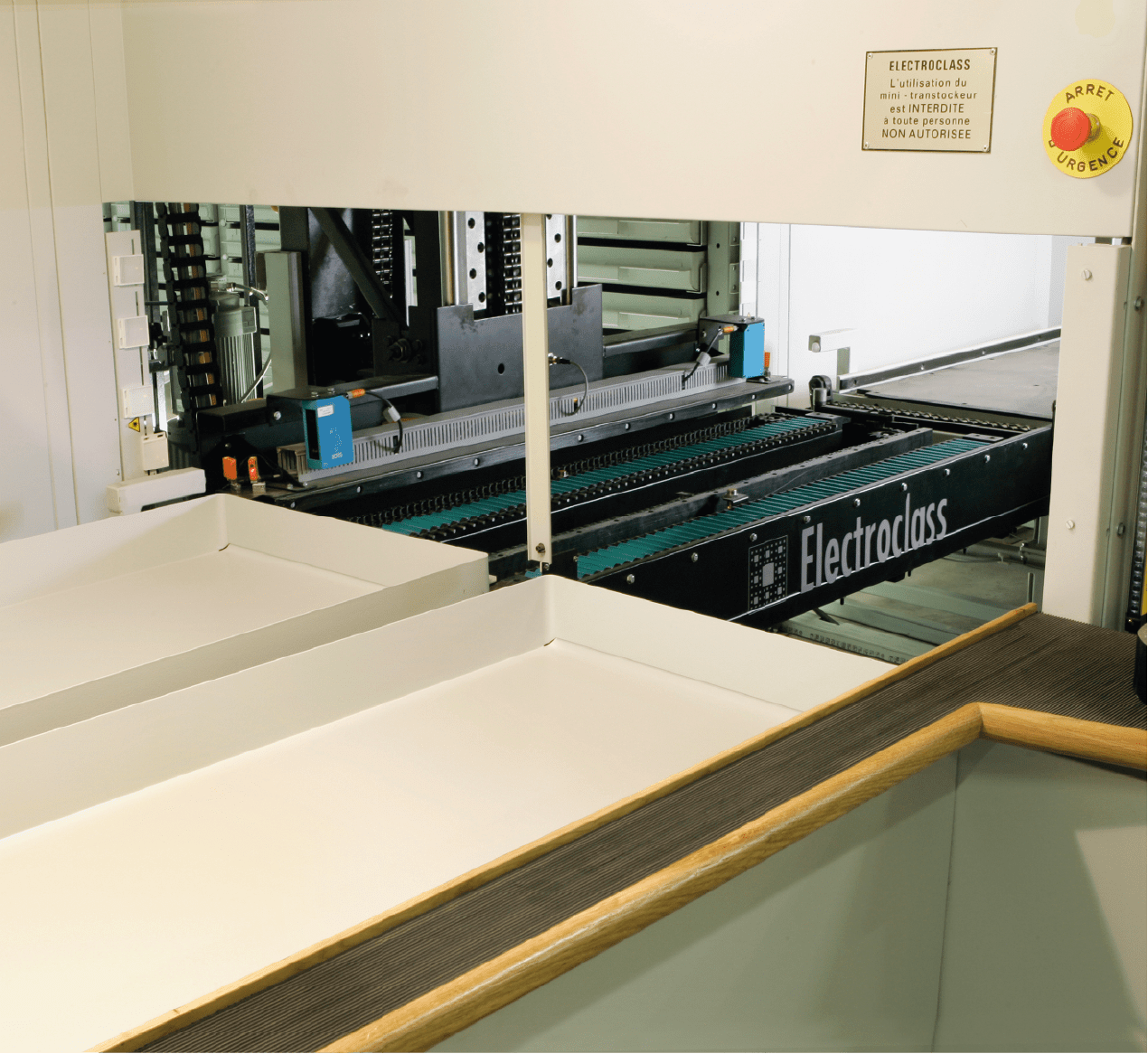

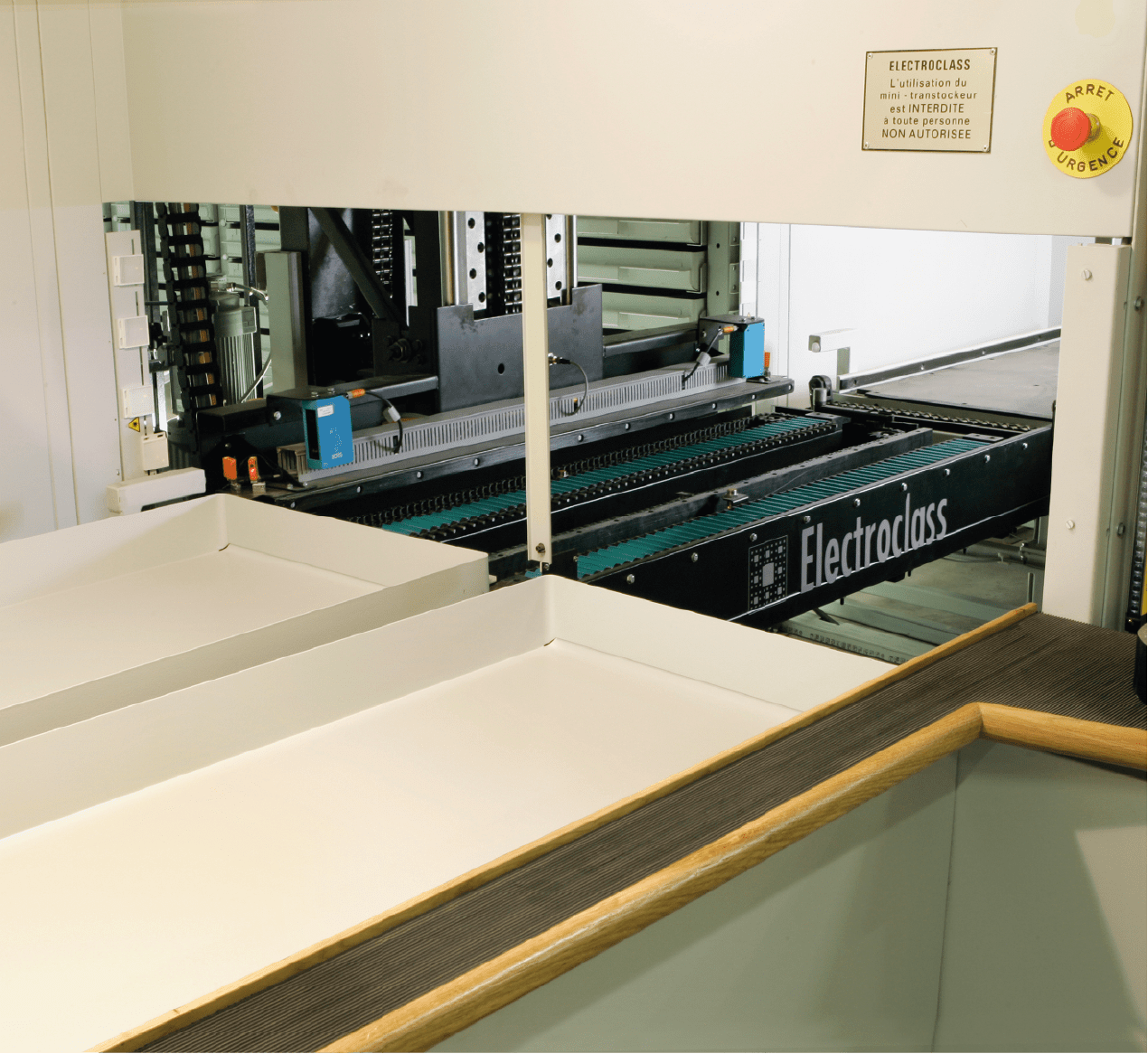

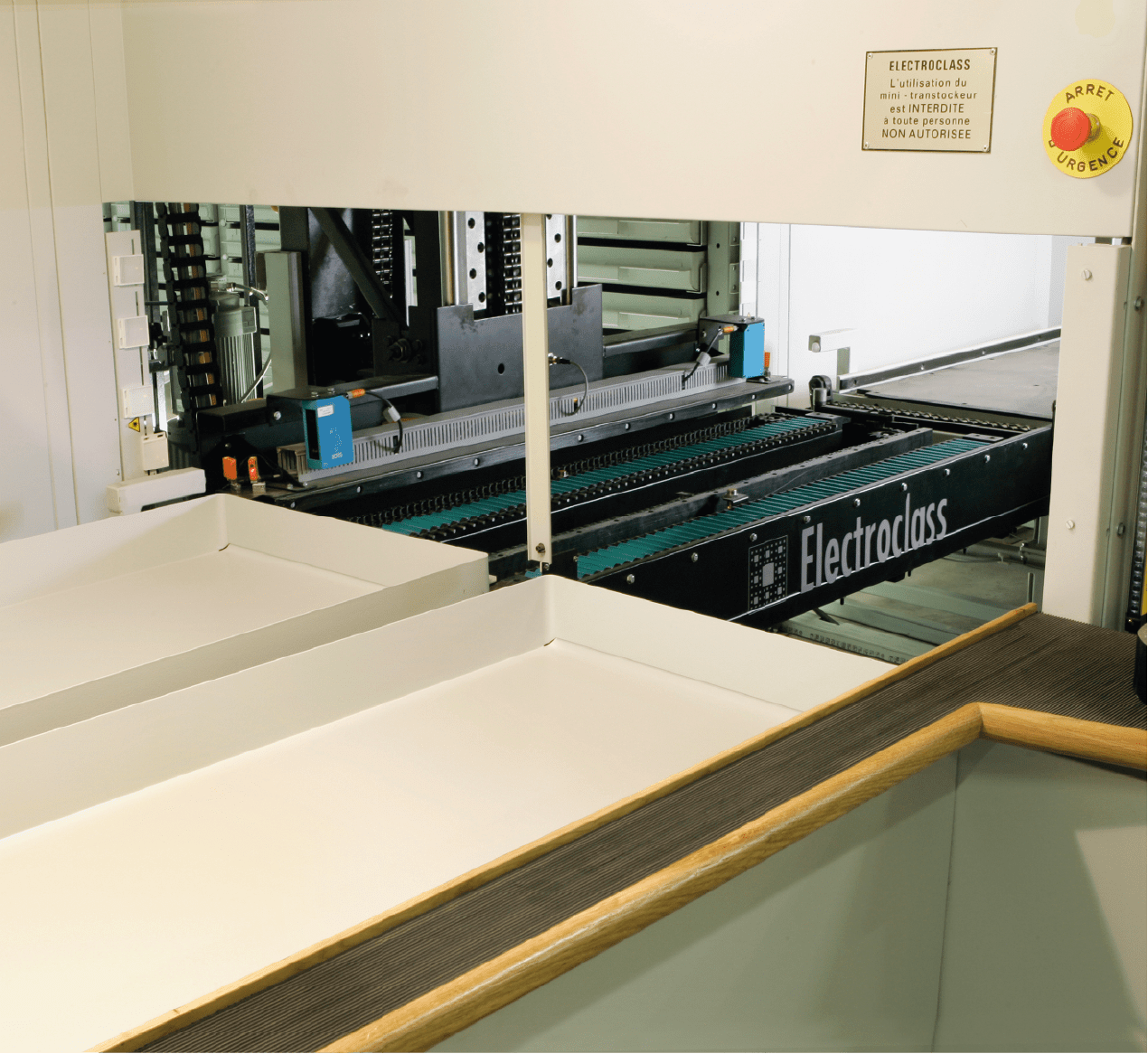

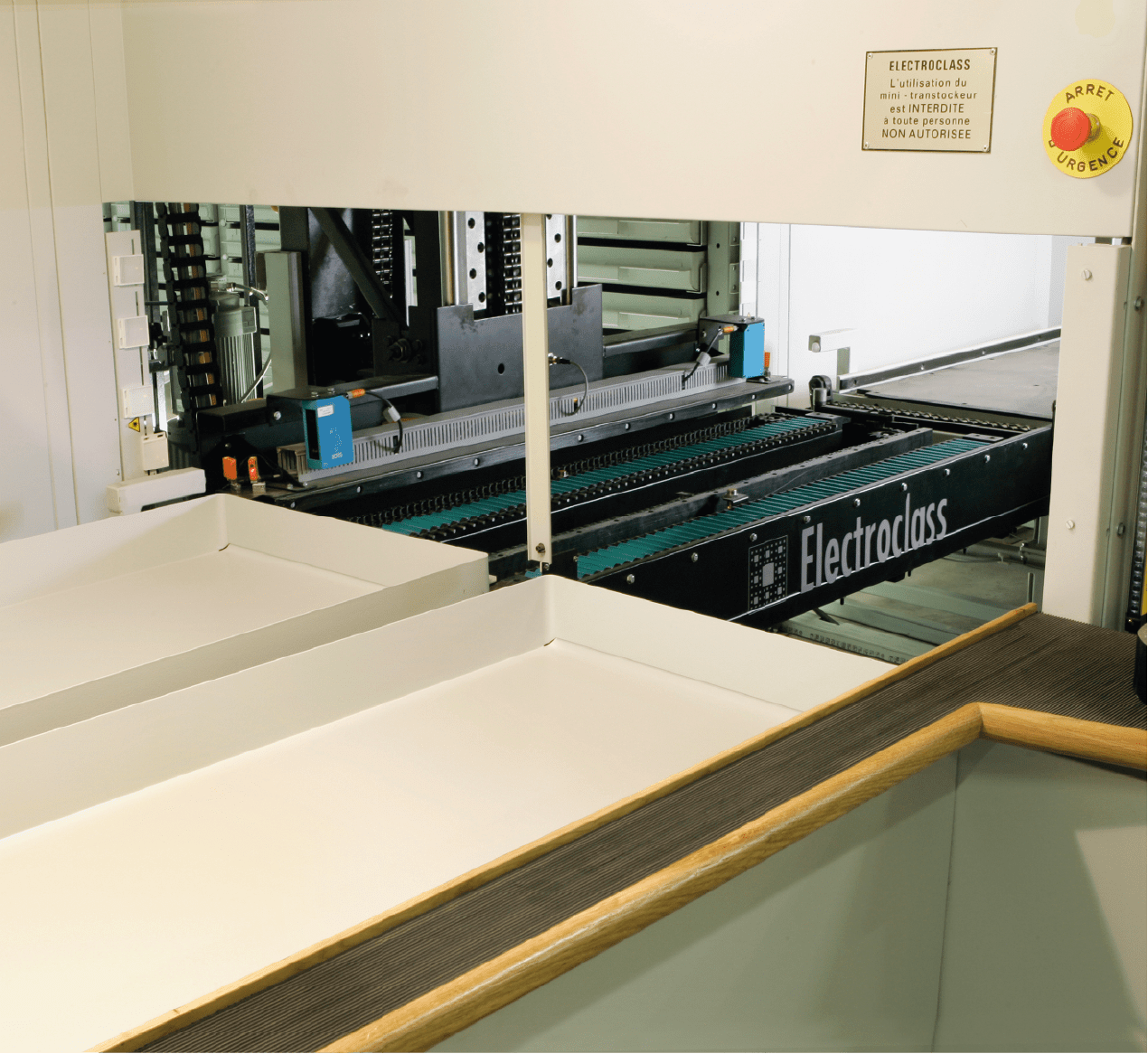

The SILO mini load storage solution stores maintenance parts (nuclear plants, production sites) / spare parts weighing over 300 kg inside a mechanically-welded structure providing capacity up to 1,000 m² / 800 m³. The two front-located viewing/work stations provide simultaneous access to several references enabling you to optimize replenishment/removal cycle time.

Would you like to optimize your order picking process?

Combined with the G-STOCK WMS software and interfaced with your ERP, the SILO ASRS automated storer ensures your large volume-size item order picking (DIY items, cardboard boxes, etc.). The SILO is replenished and orders are picked via a storer-integrated pick-to-light to make operators' work easier: in this way user productivity is increased and musculoskeletal disorders and injuries are prevented.

Would you like to improve your MRO by automating your warehouse?

By implementing a SILO automated storage solution you no longer need to pick your large volume-size products stored at heights on the racks: in addition to offering you much more security and safety, this solution also ensures your picking time is greatly reduced. So, you're rolling out an optimally-competitive organization when you use the SILO ASRS!

Would you like to reduce picking errors and increase your productivity?

By using the dynamic SILO storer and its control systems you reduce replenishment / removal errors significantly: stock differences and picking errors are a thing of the past. These benefits ensure your business becomes optimally productive whilst, at the same time, reducing operating losses.

Is it vital for you to manage your environment in a controlled way?

The SILO ASRS offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

The SILO mini load storage solution stores maintenance parts (nuclear plants, production sites) / spare parts weighing over 300 kg inside a mechanically-welded structure providing capacity up to 1,000 m² / 800 m³. The two front-located viewing/work stations provide simultaneous access to several references enabling you to optimize replenishment/removal cycle time.

Combined with the G-STOCK WMS software and interfaced with your ERP, the SILO ASRS automated storer ensures your large volume-size item order picking (DIY items, cardboard boxes, etc.). The SILO is replenished and orders are picked via a storer-integrated pick-to-light to make operators' work easier: in this way user productivity is increased and musculoskeletal disorders and injuries are prevented.

By implementing a SILO automated storage solution you no longer need to pick your large volume-size products stored at heights on the racks: in addition to offering you much more security and safety, this solution also ensures your picking time is greatly reduced. So, you're rolling out an optimally-competitive organization when you use the SILO ASRS!

By using the dynamic SILO storer and its control systems you reduce replenishment / removal errors significantly: stock differences and picking errors are a thing of the past. These benefits ensure your business becomes optimally productive whilst, at the same time, reducing operating losses.

The SILO ASRS offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

Technical arguments

A high-quality product dedicated to your optimization

The uncomplicated, robust SILO optimizes your large-size volume item management!

Fonctionnalités

Multidirectional Platform

Multidirectional Platform

The robot's manual controls, located on the door of the on-board electrical cabinet, make it possible to check the presence of the supply voltages (24 V of control) and the presence or absence of an onboard fault.

Laser measurements

Laser measurements

Managing movements using laser measurements ensures total control of the robot's position (1/10th mm).

Power supply

The power and the PLC network are transmitted to the robot via current consumers.

These slide in copper conductor rails fixed to the upper rails of the installation.

This system avoids having a power string at the rear of the robot which allows the high speeds and accelerations thereof.

There are six power outlets, including one for the land. This device is doubled to obtain excellent resistance to micro-cuts.

It is also a safety for the people involved in the machine.

Heavy-duty epoxy paint

The Stacker crane mechanically-welded structure as well as its steel cladding panels undergo full surface treatment followed by the application of epoxy power coating. This treatment offers the SILO a high-quality finish and ensures it is built to last.

Electrical equipment

Electrical equipment

All electrical equipment is as standard industrial supply.

It’s a machine easy to service and to troubleshoot and to use

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

Control panel

Control panel

The stacker crane SILO is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Class 4 safety light curtains

Class 4 safety light curtains

Like all ELECTROCLASS storage solutions, By incorporating safety light curtains which meet the 15095 + A1 standard, the SILO Miniload complies with all the provisions of the Directive 2006/42/CE on machinery

Space gain

Space gain

The drawer and removable partitioning solution ensures you optimize your volumes as much as possible. There is no space-waste as there is no forklift.

A high-quality product dedicated to your optimization

The uncomplicated, robust SILO optimizes your large-size volume item management!

Fonctionnalités

Multidirectional Platform

Multidirectional Platform

The robot's manual controls, located on the door of the on-board electrical cabinet, make it possible to check the presence of the supply voltages (24 V of control) and the presence or absence of an onboard fault.

Laser measurements

Laser measurements

Managing movements using laser measurements ensures total control of the robot's position (1/10th mm).

The power and the PLC network are transmitted to the robot via current consumers. These slide in copper conductor rails fixed to the upper rails of the installation. This system avoids having a power string at the rear of the robot which allows the high speeds and accelerations thereof. There are six power outlets, including one for the land. This device is doubled to obtain excellent resistance to micro-cuts. It is also a safety for the people involved in the machine.

The Stacker crane mechanically-welded structure as well as its steel cladding panels undergo full surface treatment followed by the application of epoxy power coating. This treatment offers the SILO a high-quality finish and ensures it is built to last.

Electrical equipment

Electrical equipment

All electrical equipment is as standard industrial supply. It’s a machine easy to service and to troubleshoot and to use

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

Control panel

Control panel

The stacker crane SILO is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Class 4 safety light curtains

Class 4 safety light curtains

Like all ELECTROCLASS storage solutions, By incorporating safety light curtains which meet the 15095 + A1 standard, the SILO Miniload complies with all the provisions of the Directive 2006/42/CE on machinery

Space gain

Space gain

The drawer and removable partitioning solution ensures you optimize your volumes as much as possible. There is no space-waste as there is no forklift.

Have you got a specific project?

We'd be delighted to hear from you!

Range

A wide range of products

Options

The transstockeur SILO just like any Electroclass machine, can be equipped with area indicators. With indicators set every 25 mm, visual identification is always highly accurate. These indicators may be lit up individually or in clusters to identify a whole area.

The SILO can be equipped with an electric curtain which totally closes the access bay. This option is useful pour parts which must remain at constant temperature or atmosphere.

We offer secure access to the stacker crane via a reader configured according to your badge technology: you reuse your current badge to access your stock safely

Transstockeurs Silocan be equipped with ventilation systems (CMV), with systems for ensuring temperature and humidity remain constant as well as a cooling unit, etc. They can also be equipped with fire detection and gas injection systems.

The oak table offers a high quality finish to the viewing bay.

With their 50 mm spacing are designed in galvanized sheet metal and offer the opportunity to compartmentalize a drawer. These features, linked to the area indicators are used to organize the contents of drawers optimally

The weighing scale option should be integrated whenever the load borne by the Silo drawers needs to be monitored. The weight is displayed on the touch screen.

Have you got a specific project?

We'd be delighted to hear from you!

Have you got a specific project?

We'd be delighted to hear from you!

Make your warehouse smart thanks to the Silo ASRS !

The SILO ASRS automated storer, consisting of two racking systems and an automated trolley and crane system moving along the central aisle: offers you short access times, optimal storage space management, high handling throughput as well as optimal access to small and large volume-size supplies.

The Silo ASRS stores all types of parts and/or boxes quickly, flexibly and reliably, so that you can:

- optimize your storage space

- secure your products

- simplify your stock management through our G-STOCK WMS software

- increase your productivity

The SILO ASRS automated storer, consisting of two racking systems and an automated trolley and crane system moving along the central aisle: offers you short access times, optimal storage space management, high handling throughput as well as optimal access to small and large volume-size supplies.

The Silo ASRS stores all types of parts and/or boxes quickly, flexibly and reliably, so that you can:

- optimize your storage space

- secure your products

- simplify your stock management through our G-STOCK WMS software

- increase your productivity

On-site issues

Do you need to manage your maintenance parts more optimally?

The SILO mini load storage solution stores maintenance parts (nuclear plants, production sites) / spare parts weighing over 300 kg inside a mechanically-welded structure providing capacity up to 1,000 m² / 800 m³. The two front-located viewing/work stations provide simultaneous access to several references enabling you to optimize replenishment/removal cycle time.

Would you like to optimize your order picking process?

Combined with the G-STOCK WMS software and interfaced with your ERP, the SILO ASRS automated storer ensures your large volume-size item order picking (DIY items, cardboard boxes, etc.). The SILO is replenished and orders are picked via a storer-integrated pick-to-light to make operators' work easier: in this way user productivity is increased and musculoskeletal disorders and injuries are prevented.

Would you like to improve your MRO by automating your warehouse?

By implementing a SILO automated storage solution you no longer need to pick your large volume-size products stored at heights on the racks: in addition to offering you much more security and safety, this solution also ensures your picking time is greatly reduced. So, you're rolling out an optimally-competitive organization when you use the SILO ASRS!

Would you like to reduce picking errors and increase your productivity?

By using the dynamic SILO storer and its control systems you reduce replenishment / removal errors significantly: stock differences and picking errors are a thing of the past. These benefits ensure your business becomes optimally productive whilst, at the same time, reducing operating losses.

Is it vital for you to manage your environment in a controlled way?

The SILO ASRS offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

The SILO mini load storage solution stores maintenance parts (nuclear plants, production sites) / spare parts weighing over 300 kg inside a mechanically-welded structure providing capacity up to 1,000 m² / 800 m³. The two front-located viewing/work stations provide simultaneous access to several references enabling you to optimize replenishment/removal cycle time.

Combined with the G-STOCK WMS software and interfaced with your ERP, the SILO ASRS automated storer ensures your large volume-size item order picking (DIY items, cardboard boxes, etc.). The SILO is replenished and orders are picked via a storer-integrated pick-to-light to make operators' work easier: in this way user productivity is increased and musculoskeletal disorders and injuries are prevented.

By implementing a SILO automated storage solution you no longer need to pick your large volume-size products stored at heights on the racks: in addition to offering you much more security and safety, this solution also ensures your picking time is greatly reduced. So, you're rolling out an optimally-competitive organization when you use the SILO ASRS!

By using the dynamic SILO storer and its control systems you reduce replenishment / removal errors significantly: stock differences and picking errors are a thing of the past. These benefits ensure your business becomes optimally productive whilst, at the same time, reducing operating losses.

The SILO ASRS offers controlled environment storage (temperature, humidity, etc.) for all your sensitive parts (silicone, rubber, etc.). As such, you are real-time informed whenever the tolerance grades are no longer complied with.

Technical arguments

A high-quality product dedicated to your optimization

The uncomplicated, robust SILO optimizes your large-size volume item management!

Fonctionnalités

Multidirectional Platform

Multidirectional Platform

The robot's manual controls, located on the door of the on-board electrical cabinet, make it possible to check the presence of the supply voltages (24 V of control) and the presence or absence of an onboard fault.

Laser measurements

Laser measurements

Managing movements using laser measurements ensures total control of the robot's position (1/10th mm).

Power supply

The power and the PLC network are transmitted to the robot via current consumers.

These slide in copper conductor rails fixed to the upper rails of the installation.

This system avoids having a power string at the rear of the robot which allows the high speeds and accelerations thereof.

There are six power outlets, including one for the land. This device is doubled to obtain excellent resistance to micro-cuts.

It is also a safety for the people involved in the machine.

Heavy-duty epoxy paint

The Stacker crane mechanically-welded structure as well as its steel cladding panels undergo full surface treatment followed by the application of epoxy power coating. This treatment offers the SILO a high-quality finish and ensures it is built to last.

Electrical equipment

Electrical equipment

All electrical equipment is as standard industrial supply.

It’s a machine easy to service and to troubleshoot and to use

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

Control panel

Control panel

The stacker crane SILO is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Class 4 safety light curtains

Class 4 safety light curtains

Like all ELECTROCLASS storage solutions, By incorporating safety light curtains which meet the 15095 + A1 standard, the SILO Miniload complies with all the provisions of the Directive 2006/42/CE on machinery

Space gain

Space gain

The drawer and removable partitioning solution ensures you optimize your volumes as much as possible. There is no space-waste as there is no forklift.

A high-quality product dedicated to your optimization

The uncomplicated, robust SILO optimizes your large-size volume item management!

Fonctionnalités

Multidirectional Platform

Multidirectional Platform

The robot's manual controls, located on the door of the on-board electrical cabinet, make it possible to check the presence of the supply voltages (24 V of control) and the presence or absence of an onboard fault.

Laser measurements

Laser measurements

Managing movements using laser measurements ensures total control of the robot's position (1/10th mm).

The power and the PLC network are transmitted to the robot via current consumers. These slide in copper conductor rails fixed to the upper rails of the installation. This system avoids having a power string at the rear of the robot which allows the high speeds and accelerations thereof. There are six power outlets, including one for the land. This device is doubled to obtain excellent resistance to micro-cuts. It is also a safety for the people involved in the machine.

The Stacker crane mechanically-welded structure as well as its steel cladding panels undergo full surface treatment followed by the application of epoxy power coating. This treatment offers the SILO a high-quality finish and ensures it is built to last.

Electrical equipment

Electrical equipment

All electrical equipment is as standard industrial supply. It’s a machine easy to service and to troubleshoot and to use

HDPE drawer guides (High-density polyethylene)

HDPE drawer guides (High-density polyethylene)

The guides installed under the drawers also facilitate removal and eliminate risk of ferrous residue in the tower.

Control panel

Control panel

The stacker crane SILO is equipped with a LCD touch screen control panel for operating the tower. This control panel offers outstanding display viewability and is used to call the drawers, for modifying settings, for managing the indicators and all machine configuration. You can lock the control panel with an access code which will secure access to the tower and/or to specific drawers.

Class 4 safety light curtains

Class 4 safety light curtains

Like all ELECTROCLASS storage solutions, By incorporating safety light curtains which meet the 15095 + A1 standard, the SILO Miniload complies with all the provisions of the Directive 2006/42/CE on machinery

Space gain

Space gain

The drawer and removable partitioning solution ensures you optimize your volumes as much as possible. There is no space-waste as there is no forklift.

Have you got a specific project?

We'd be delighted to hear from you!

Range

A wide range of products

Options

The transstockeur SILO just like any Electroclass machine, can be equipped with area indicators. With indicators set every 25 mm, visual identification is always highly accurate. These indicators may be lit up individually or in clusters to identify a whole area.

The SILO can be equipped with an electric curtain which totally closes the access bay. This option is useful pour parts which must remain at constant temperature or atmosphere.

We offer secure access to the stacker crane via a reader configured according to your badge technology: you reuse your current badge to access your stock safely

Transstockeurs Silocan be equipped with ventilation systems (CMV), with systems for ensuring temperature and humidity remain constant as well as a cooling unit, etc. They can also be equipped with fire detection and gas injection systems.

The oak table offers a high quality finish to the viewing bay.

With their 50 mm spacing are designed in galvanized sheet metal and offer the opportunity to compartmentalize a drawer. These features, linked to the area indicators are used to organize the contents of drawers optimally

The weighing scale option should be integrated whenever the load borne by the Silo drawers needs to be monitored. The weight is displayed on the touch screen.

Have you got a specific project?

We'd be delighted to hear from you!

Have you got a specific project?

We'd be delighted to hear from you!