Breadcrumbs

G-STOCK WMS software

G-STOCK software: the WMS for warehouses and machining shops!

G-STOCK, published by Electroclass, is best-in-class WMS for:

- Optimizing inputs and outputs based on Machining shop or Warehouse organization criteria either autonomously or linked to an ERP

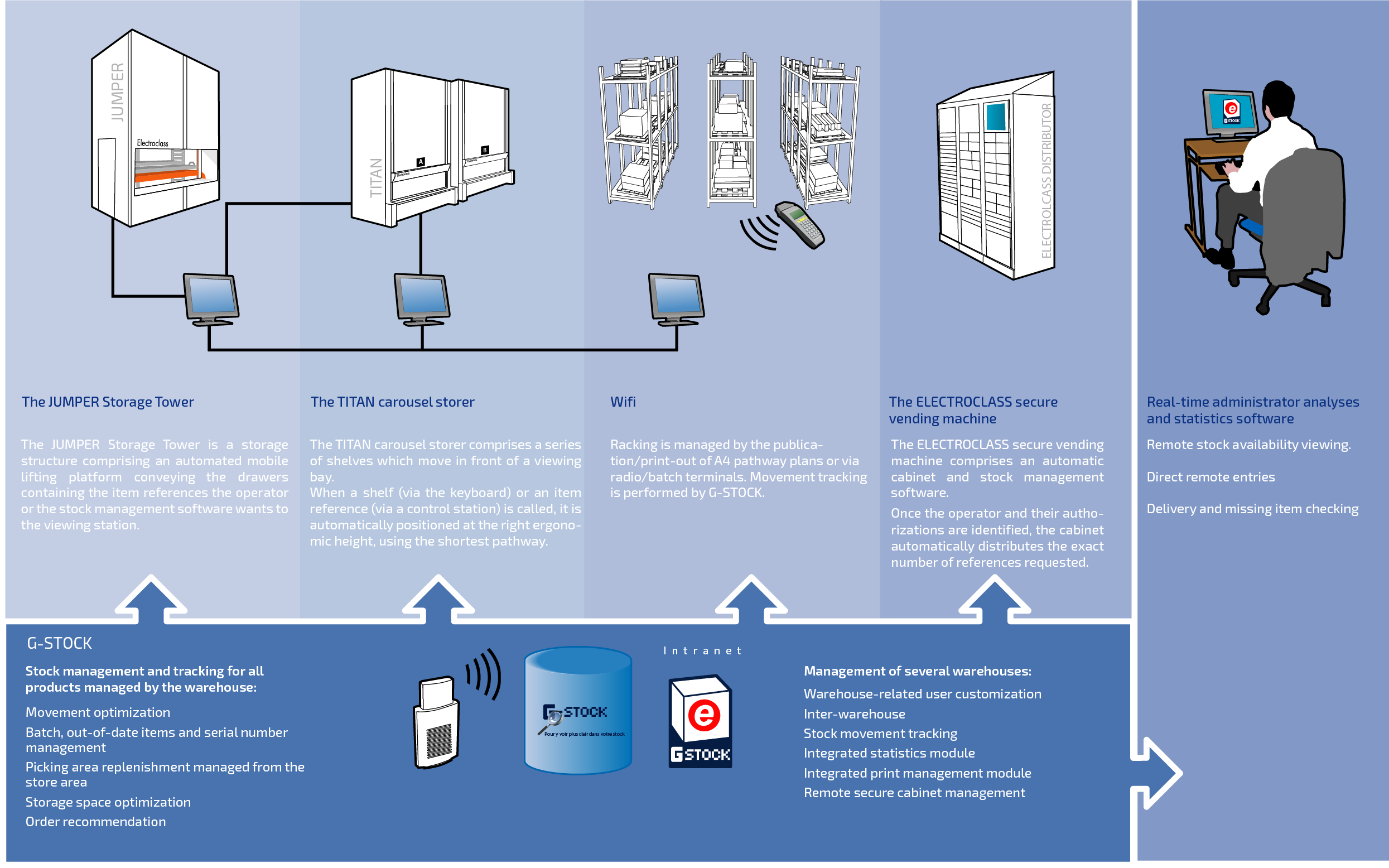

- Managing and operating different types of automated racking storage solutions (TITAN storer, JUMPER storage tower, SILO ASRS), as well as managing remote stock and managing stores

- Managing product stocks and their storage spaces to optimize input/output movements

- Ensuring all stock movements are tracked (batch, expiry/useby, serialized products, etc.) and organizing part flows in each area of the warehouse/store/shop

- Keeping a comprehensive update of the storage spaces and realtime providing shop/store managers and staff with the information required for their business to operate and be organized optimally

G-STOCK, published by Electroclass, is best-in-class WMS for:

- Optimizing inputs and outputs based on Machining shop or Warehouse organization criteria either autonomously or linked to an ERP

- Managing and operating different types of automated racking storage solutions (TITAN storer, JUMPER storage tower, SILO ASRS), as well as managing remote stock and managing stores

- Managing product stocks and their storage spaces to optimize input/output movements

- Ensuring all stock movements are tracked (batch, expiry/useby, serialized products, etc.) and organizing part flows in each area of the warehouse/store/shop

- Keeping a comprehensive update of the storage spaces and realtime providing shop/store managers and staff with the information required for their business to operate and be organized optimally

Customer issues

Would you like to optimize the stock in your central production warehouse?

The G-STOCK software ensures stock integrity and tracks all movements requested by Production Management (CAPM) which transmits the Production Order list for picking and receipts made to the software. It can also manage automated stock replenishment based on minimum quantity limits selected for each space.

Would you like to enhance your order picking throughput?

The G-STOCK WMS prints a pathway plan tracing the pallets and products to be taken out by setting up the shortest round to be made. Once picking is over, the operator validates their round once only. A summary output slip (a pick ticket) is then issued for this order. During receipts, G-STOCK automatically proposes the most appropriate spaces for each pallet based on each product capacity.

Would you like to set up a self-service warehouse?

When linked to automated storers or secure vending machines, G-STOCK can be used to serve in-stock products 24/7 and ensure optimal tracking. G-STOCK allows you to manage part availability based on operators and also manages tooling and other equipment loans.

Would you like to keep track of your maintenance parts?

G-STOCK manages the maintenance stock whilst tracking all movements made and can track consumption recorded for the various machines so as to create repair statistics. It automatically launches replenishment of stockout parts or parts which have reached minimum stock and memorizes unfulfilled requests (missing or owed).

Would you like to manage several warehouses with one management software?

G-STOCK enables you to manage several warehouses integrating storage systems with one software which uses an all-in warehouse management interface from receipt through to shipment. The warehouse staff, real-time connected to the stock and the storage spaces, can view stock errors and can make transfers, replenishment and inputs/outputs without having to return to their computer.

The G-STOCK software ensures stock integrity and tracks all movements requested by Production Management (CAPM) which transmits the Production Order list for picking and receipts made to the software. It can also manage automated stock replenishment based on minimum quantity limits selected for each space.

The G-STOCK WMS prints a pathway plan tracing the pallets and products to be taken out by setting up the shortest round to be made. Once picking is over, the operator validates their round once only. A summary output slip (a pick ticket) is then issued for this order. During receipts, G-STOCK automatically proposes the most appropriate spaces for each pallet based on each product capacity.

When linked to automated storers or secure vending machines, G-STOCK can be used to serve in-stock products 24/7 and ensure optimal tracking. G-STOCK allows you to manage part availability based on operators and also manages tooling and other equipment loans.

G-STOCK manages the maintenance stock whilst tracking all movements made and can track consumption recorded for the various machines so as to create repair statistics. It automatically launches replenishment of stockout parts or parts which have reached minimum stock and memorizes unfulfilled requests (missing or owed).

G-STOCK enables you to manage several warehouses integrating storage systems with one software which uses an all-in warehouse management interface from receipt through to shipment. The warehouse staff, real-time connected to the stock and the storage spaces, can view stock errors and can make transfers, replenishment and inputs/outputs without having to return to their computer.

Technical arguments

High-quality software dedicated to your optimization

The G-STOCK WMS software is designed to improve storage techniques, enhance comfort, user-friendliness and to ensure you save considerable time on a daily basis.

Fonctionnalités

100% ELECTROCLASS software

100% ELECTROCLASS software

The G-STOCK WMS software is developed on our premises in Bussy-Saint-Georges which means we can offer you special high-quality developments within a very short timeframe.

100% ELECTROCLASS technical team

100% ELECTROCLASS technical team

Our project managers and integrators are on-hand to offer you software perfectly tailored to your needs. A G-STOCK-dedicated Hotline is also located on our premises in Bussy-St-Georges

Customizable software

Customizable software

G-STOCK lets you view all information and stock from the database through customizable, saved queries or user-generated queries. G-STOCK organizes part flows in each area of the warehouse.

Enhanced tracking management

Enhanced tracking management

The G-STOCK software manages the logistics flows for the various areas in your warehouse/store/shop. G-STOCK ensures all stock movements are tracked (batch, expiry/use-by, serialized products, etc.). This feature enables instant removal, transfer or quarantine for an obsolete batch and/or product along with (or without) space transfer.

Secure access

Secure access

The G-STOCK software may also be accessed using password identification or a badge reader (depending on your badging technology).

Real-time inventory data management

Real-time inventory data management

G-STOCK keeps a comprehensive update of the storage spaces, volumes occupied or available and real-time provides warehouse/shop/store managers and staff with the information required for their business to operate optimally.

Interfaces with all types of ERP

Interfaces with all types of ERP

The G-STOCK software interfaces with all types of ERP available on the market

High-quality software dedicated to your optimization

The G-STOCK WMS software is designed to improve storage techniques, enhance comfort, user-friendliness and to ensure you save considerable time on a daily basis.

Fonctionnalités

100% ELECTROCLASS software

100% ELECTROCLASS software

The G-STOCK WMS software is developed on our premises in Bussy-Saint-Georges which means we can offer you special high-quality developments within a very short timeframe.

100% ELECTROCLASS technical team

100% ELECTROCLASS technical team

Our project managers and integrators are on-hand to offer you software perfectly tailored to your needs. A G-STOCK-dedicated Hotline is also located on our premises in Bussy-St-Georges

Customizable software

Customizable software

G-STOCK lets you view all information and stock from the database through customizable, saved queries or user-generated queries. G-STOCK organizes part flows in each area of the warehouse.

Enhanced tracking management

Enhanced tracking management

The G-STOCK software manages the logistics flows for the various areas in your warehouse/store/shop. G-STOCK ensures all stock movements are tracked (batch, expiry/use-by, serialized products, etc.). This feature enables instant removal, transfer or quarantine for an obsolete batch and/or product along with (or without) space transfer.

Secure access

Secure access

The G-STOCK software may also be accessed using password identification or a badge reader (depending on your badging technology).

Real-time inventory data management

Real-time inventory data management

G-STOCK keeps a comprehensive update of the storage spaces, volumes occupied or available and real-time provides warehouse/shop/store managers and staff with the information required for their business to operate optimally.

Interfaces with all types of ERP

Interfaces with all types of ERP

The G-STOCK software interfaces with all types of ERP available on the market

Have you got a specific project?

We'd be delighted to hear from you! Get in touch.

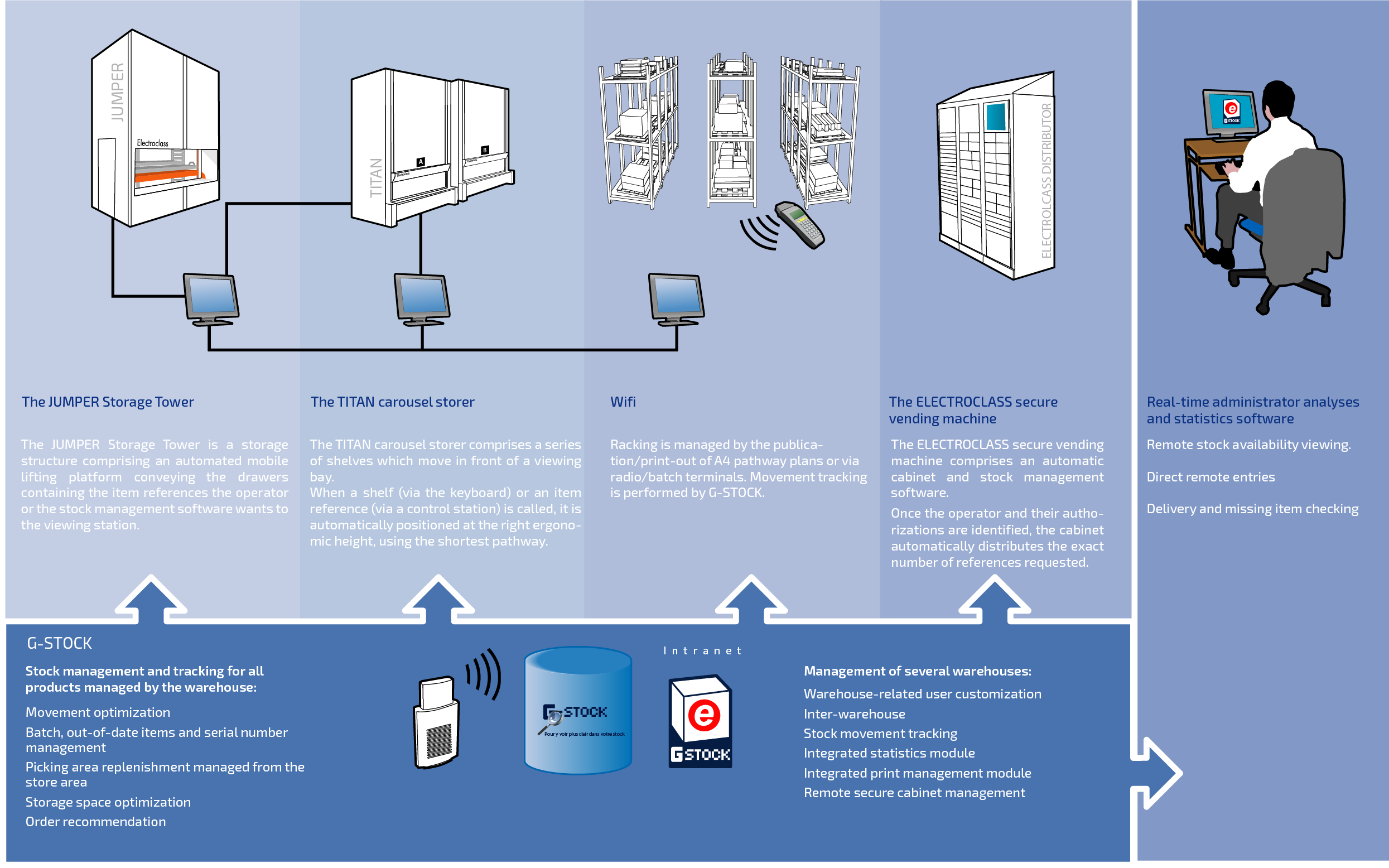

Architecture

Software suites

The all-in G-STOCK software manages all logistics flows inside the warehouse from package arrival through to part shipment, including all intermediary phases. This software enables you to manage all the ins and outs of the supply chain easily through the webservice.

The G-STOCK WMS software manages the logistics flows for the various areas of your warehouse/store/shop.

It enables:

- Removal

- Transfer

- Or instant quarantine.

The single-user G-STOCK management software only manages inputs and outputs for storers managed by the control station in your warehouse or store. The single-user G-STOCK management software can manage Electroclass storers as well as those of other brands.

The remote G-STOCK software enables you to manage your stocks and spaces in areas which are not linked to your ERP or LIS (Logistics Information System).

Have you got a specific project?

We'd be delighted to hear from you! Get in touch.

G-STOCK software: the WMS for warehouses and machining shops!

G-STOCK, published by Electroclass, is best-in-class WMS for:

- Optimizing inputs and outputs based on Machining shop or Warehouse organization criteria either autonomously or linked to an ERP

- Managing and operating different types of automated racking storage solutions (TITAN storer, JUMPER storage tower, SILO ASRS), as well as managing remote stock and managing stores

- Managing product stocks and their storage spaces to optimize input/output movements

- Ensuring all stock movements are tracked (batch, expiry/useby, serialized products, etc.) and organizing part flows in each area of the warehouse/store/shop

- Keeping a comprehensive update of the storage spaces and realtime providing shop/store managers and staff with the information required for their business to operate and be organized optimally

G-STOCK, published by Electroclass, is best-in-class WMS for:

- Optimizing inputs and outputs based on Machining shop or Warehouse organization criteria either autonomously or linked to an ERP

- Managing and operating different types of automated racking storage solutions (TITAN storer, JUMPER storage tower, SILO ASRS), as well as managing remote stock and managing stores

- Managing product stocks and their storage spaces to optimize input/output movements

- Ensuring all stock movements are tracked (batch, expiry/useby, serialized products, etc.) and organizing part flows in each area of the warehouse/store/shop

- Keeping a comprehensive update of the storage spaces and realtime providing shop/store managers and staff with the information required for their business to operate and be organized optimally

Customer issues

Would you like to optimize the stock in your central production warehouse?

The G-STOCK software ensures stock integrity and tracks all movements requested by Production Management (CAPM) which transmits the Production Order list for picking and receipts made to the software. It can also manage automated stock replenishment based on minimum quantity limits selected for each space.

Would you like to enhance your order picking throughput?

The G-STOCK WMS prints a pathway plan tracing the pallets and products to be taken out by setting up the shortest round to be made. Once picking is over, the operator validates their round once only. A summary output slip (a pick ticket) is then issued for this order. During receipts, G-STOCK automatically proposes the most appropriate spaces for each pallet based on each product capacity.

Would you like to set up a self-service warehouse?

When linked to automated storers or secure vending machines, G-STOCK can be used to serve in-stock products 24/7 and ensure optimal tracking. G-STOCK allows you to manage part availability based on operators and also manages tooling and other equipment loans.

Would you like to keep track of your maintenance parts?

G-STOCK manages the maintenance stock whilst tracking all movements made and can track consumption recorded for the various machines so as to create repair statistics. It automatically launches replenishment of stockout parts or parts which have reached minimum stock and memorizes unfulfilled requests (missing or owed).

Would you like to manage several warehouses with one management software?

G-STOCK enables you to manage several warehouses integrating storage systems with one software which uses an all-in warehouse management interface from receipt through to shipment. The warehouse staff, real-time connected to the stock and the storage spaces, can view stock errors and can make transfers, replenishment and inputs/outputs without having to return to their computer.

The G-STOCK software ensures stock integrity and tracks all movements requested by Production Management (CAPM) which transmits the Production Order list for picking and receipts made to the software. It can also manage automated stock replenishment based on minimum quantity limits selected for each space.

The G-STOCK WMS prints a pathway plan tracing the pallets and products to be taken out by setting up the shortest round to be made. Once picking is over, the operator validates their round once only. A summary output slip (a pick ticket) is then issued for this order. During receipts, G-STOCK automatically proposes the most appropriate spaces for each pallet based on each product capacity.

When linked to automated storers or secure vending machines, G-STOCK can be used to serve in-stock products 24/7 and ensure optimal tracking. G-STOCK allows you to manage part availability based on operators and also manages tooling and other equipment loans.

G-STOCK manages the maintenance stock whilst tracking all movements made and can track consumption recorded for the various machines so as to create repair statistics. It automatically launches replenishment of stockout parts or parts which have reached minimum stock and memorizes unfulfilled requests (missing or owed).

G-STOCK enables you to manage several warehouses integrating storage systems with one software which uses an all-in warehouse management interface from receipt through to shipment. The warehouse staff, real-time connected to the stock and the storage spaces, can view stock errors and can make transfers, replenishment and inputs/outputs without having to return to their computer.

Technical arguments

High-quality software dedicated to your optimization

The G-STOCK WMS software is designed to improve storage techniques, enhance comfort, user-friendliness and to ensure you save considerable time on a daily basis.

Fonctionnalités

100% ELECTROCLASS software

100% ELECTROCLASS software

The G-STOCK WMS software is developed on our premises in Bussy-Saint-Georges which means we can offer you special high-quality developments within a very short timeframe.

100% ELECTROCLASS technical team

100% ELECTROCLASS technical team

Our project managers and integrators are on-hand to offer you software perfectly tailored to your needs. A G-STOCK-dedicated Hotline is also located on our premises in Bussy-St-Georges

Customizable software

Customizable software

G-STOCK lets you view all information and stock from the database through customizable, saved queries or user-generated queries. G-STOCK organizes part flows in each area of the warehouse.

Enhanced tracking management

Enhanced tracking management

The G-STOCK software manages the logistics flows for the various areas in your warehouse/store/shop. G-STOCK ensures all stock movements are tracked (batch, expiry/use-by, serialized products, etc.). This feature enables instant removal, transfer or quarantine for an obsolete batch and/or product along with (or without) space transfer.

Secure access

Secure access

The G-STOCK software may also be accessed using password identification or a badge reader (depending on your badging technology).

Real-time inventory data management

Real-time inventory data management

G-STOCK keeps a comprehensive update of the storage spaces, volumes occupied or available and real-time provides warehouse/shop/store managers and staff with the information required for their business to operate optimally.

Interfaces with all types of ERP

Interfaces with all types of ERP

The G-STOCK software interfaces with all types of ERP available on the market

High-quality software dedicated to your optimization

The G-STOCK WMS software is designed to improve storage techniques, enhance comfort, user-friendliness and to ensure you save considerable time on a daily basis.

Fonctionnalités

100% ELECTROCLASS software

100% ELECTROCLASS software

The G-STOCK WMS software is developed on our premises in Bussy-Saint-Georges which means we can offer you special high-quality developments within a very short timeframe.

100% ELECTROCLASS technical team

100% ELECTROCLASS technical team

Our project managers and integrators are on-hand to offer you software perfectly tailored to your needs. A G-STOCK-dedicated Hotline is also located on our premises in Bussy-St-Georges

Customizable software

Customizable software

G-STOCK lets you view all information and stock from the database through customizable, saved queries or user-generated queries. G-STOCK organizes part flows in each area of the warehouse.

Enhanced tracking management

Enhanced tracking management

The G-STOCK software manages the logistics flows for the various areas in your warehouse/store/shop. G-STOCK ensures all stock movements are tracked (batch, expiry/use-by, serialized products, etc.). This feature enables instant removal, transfer or quarantine for an obsolete batch and/or product along with (or without) space transfer.

Secure access

Secure access

The G-STOCK software may also be accessed using password identification or a badge reader (depending on your badging technology).

Real-time inventory data management

Real-time inventory data management

G-STOCK keeps a comprehensive update of the storage spaces, volumes occupied or available and real-time provides warehouse/shop/store managers and staff with the information required for their business to operate optimally.

Interfaces with all types of ERP

Interfaces with all types of ERP

The G-STOCK software interfaces with all types of ERP available on the market

Have you got a specific project?

We'd be delighted to hear from you! Get in touch.

Architecture

Software suites

The all-in G-STOCK software manages all logistics flows inside the warehouse from package arrival through to part shipment, including all intermediary phases. This software enables you to manage all the ins and outs of the supply chain easily through the webservice.

The G-STOCK WMS software manages the logistics flows for the various areas of your warehouse/store/shop.

It enables:

- Removal

- Transfer

- Or instant quarantine.

The single-user G-STOCK management software only manages inputs and outputs for storers managed by the control station in your warehouse or store. The single-user G-STOCK management software can manage Electroclass storers as well as those of other brands.

The remote G-STOCK software enables you to manage your stocks and spaces in areas which are not linked to your ERP or LIS (Logistics Information System).

Have you got a specific project?

We'd be delighted to hear from you! Get in touch.